I recently bought a Boyar-Shultz 6 x 12 for $300. It came with a mag chuck, end mill end grinding fixture, diamond dresser, 22 stones, and a diamond wheel. The ways are Great! Haven’t had a chance to get it into the basement to hook it up yet though. So far, the bearings seem to be OK. Hasn’t had a lot of use.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surface Grinder for a hobbyist

- Thread starter Driveslayer45

- Start date

- Joined

- Mar 5, 2019

- Messages

- 216

It sounds like you've gotten a hell of a deal. Mine doesn't seem bad for $300, although it didn't come with a Chuck or tooling. I need to work on the switch as the owner bypassed it said something about old wiring. It seems to have a multi-position switch. I also need to replace the rubber dust guards, anyone have suggestions on those?

I ordered two a vfd and some wheel dressers from Amazon, and an import mag Chuck from eBay as well as a 32 and 38 wheel to get me started.

I'm looking forward to learning how to use it

I ordered two a vfd and some wheel dressers from Amazon, and an import mag Chuck from eBay as well as a 32 and 38 wheel to get me started.

I'm looking forward to learning how to use it

- Joined

- Mar 5, 2019

- Messages

- 216

Ok, I've pulled much if the machine down inspecting and cleaning and the only thing I found that actually concerns me is the cross feed leed screw is very badly worn. The accordian boot covering it broke and looks like it's worn the screw down to pretty sharp points in a section.

I don't have the proper guages but I think the shaft is 3/4-10 lh square thread. Anyone know.

I was looking at McMaster but the design of this screw is weird, it's not fully threaded, only about 2/3 is then the thread just stops, not even a relief cut, with the rest of the shaft at a full 3/4.

Open to suggestions. My current thought is to get some 3/4 crs from my local hardware and see how many tools I can break and how many hours I can waste trying to cut a thread I've never cut before, over about 14" ....

I don't have the proper guages but I think the shaft is 3/4-10 lh square thread. Anyone know.

I was looking at McMaster but the design of this screw is weird, it's not fully threaded, only about 2/3 is then the thread just stops, not even a relief cut, with the rest of the shaft at a full 3/4.

Open to suggestions. My current thought is to get some 3/4 crs from my local hardware and see how many tools I can break and how many hours I can waste trying to cut a thread I've never cut before, over about 14" ....

- Joined

- Feb 5, 2018

- Messages

- 638

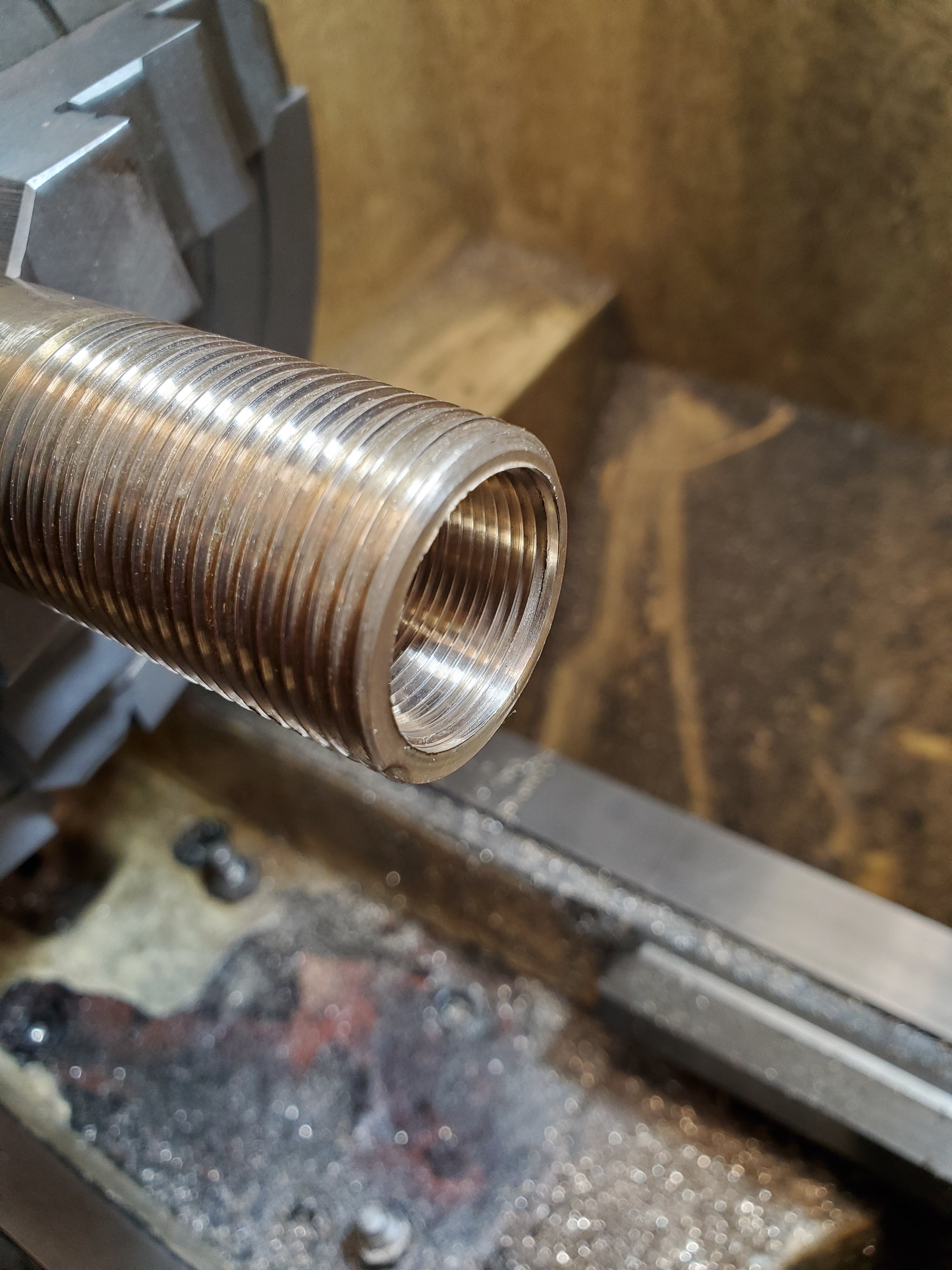

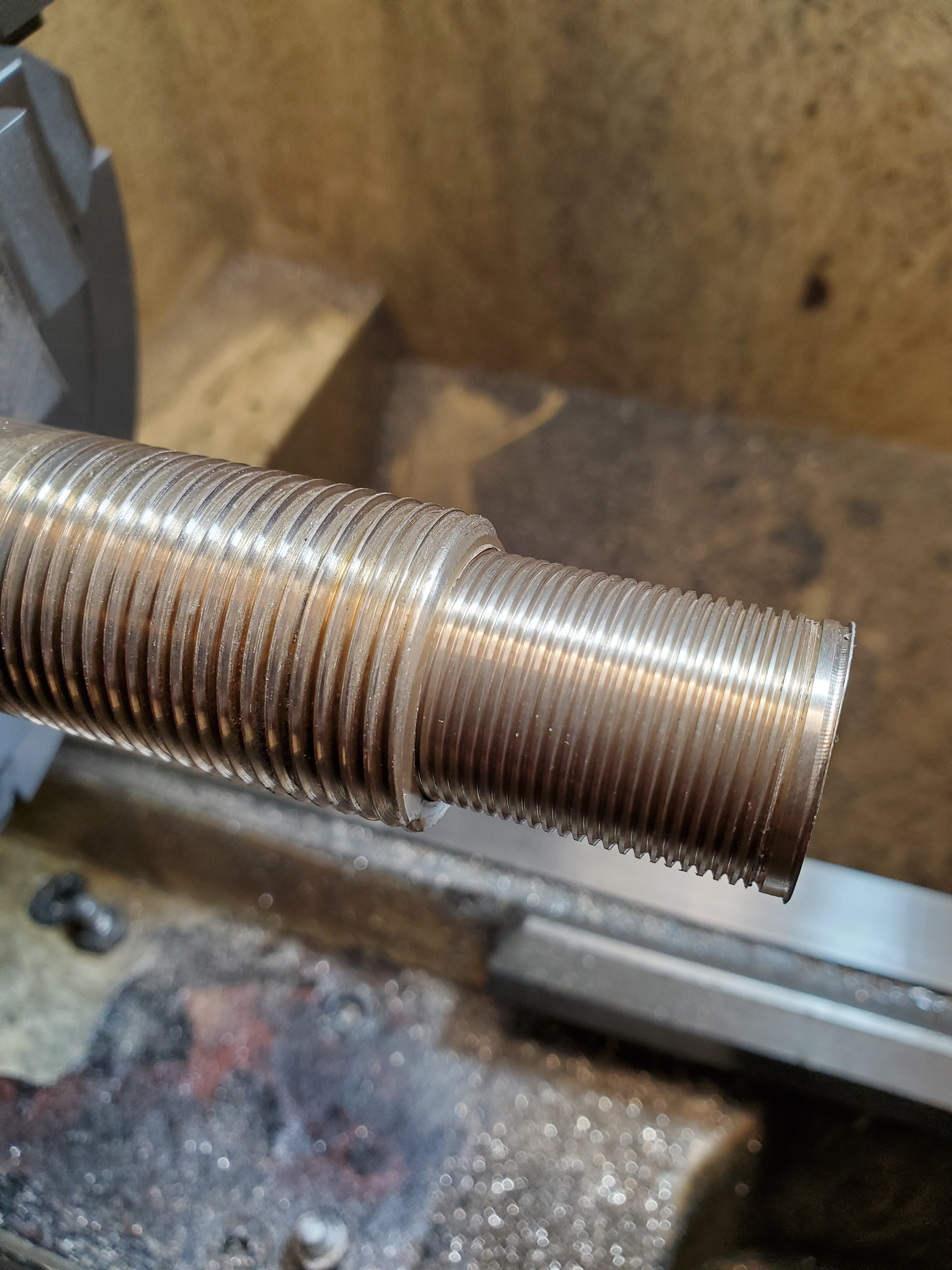

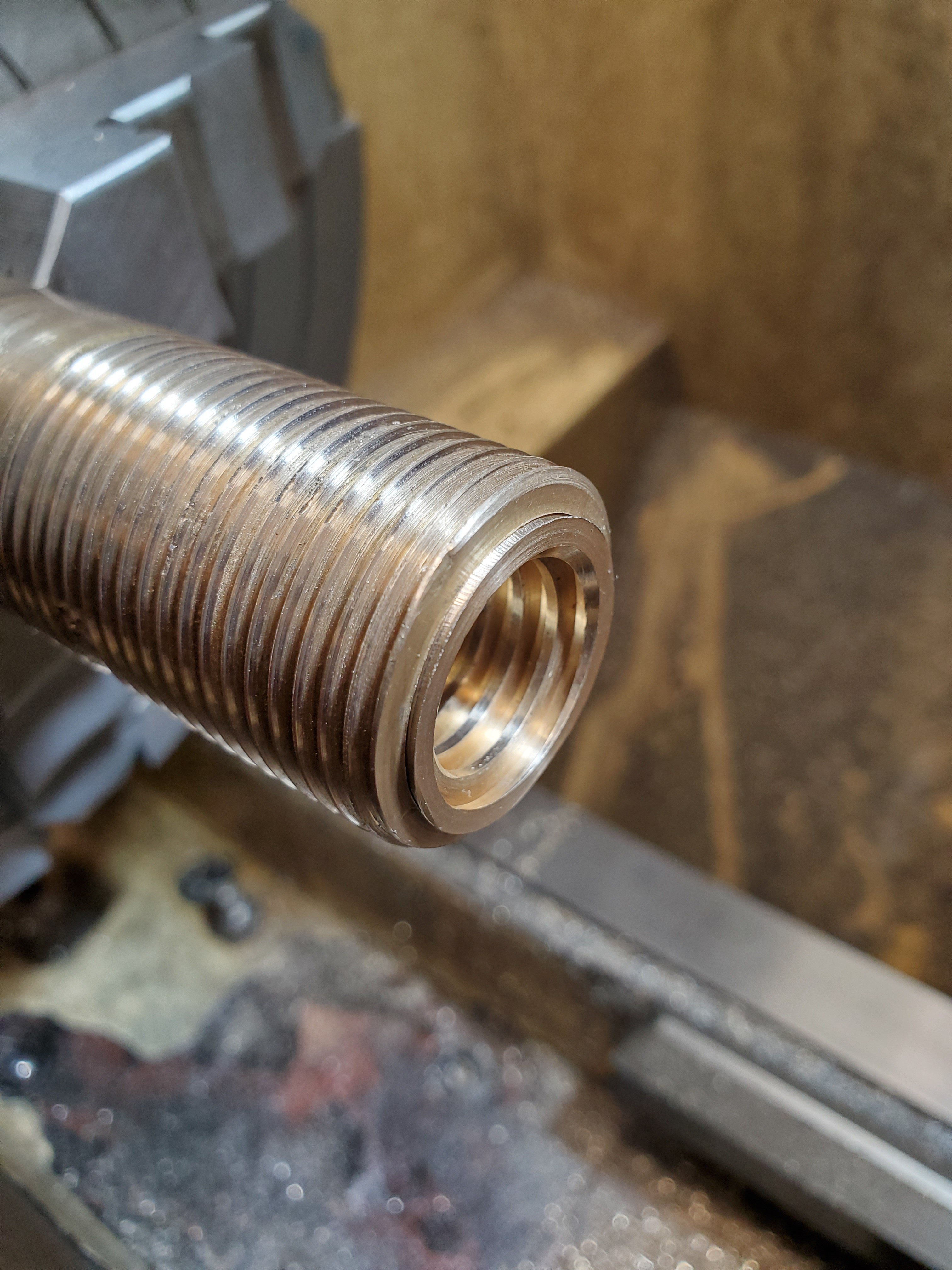

I am in the process of doing this exact same thing right now to the grinder I bought.

I bored the shaft out and made a bushing with the 3/4"×8tpi LH Acme thread and threaded it into the hole.

I also made the shaft last night. I got it threaded and need to finish the other end.

You will probably be in the same situation having to make replacement parts.

Joe

I bored the shaft out and made a bushing with the 3/4"×8tpi LH Acme thread and threaded it into the hole.

I also made the shaft last night. I got it threaded and need to finish the other end.

You will probably be in the same situation having to make replacement parts.

Joe

Attachments

- Joined

- Mar 5, 2019

- Messages

- 216

That's great. How did you measure the tpi? do you have a guage? I simply set my caliper to 1" and counted the threads between the jaws.. checking Amazon for a thread guage.. watching some videos... It does look doable

- Joined

- Feb 5, 2018

- Messages

- 638

A couple more pictures

- Joined

- Feb 5, 2018

- Messages

- 638

Here is the shaft. Its the first Acme thread I have done.

- Joined

- Feb 5, 2018

- Messages

- 638

Yeah I bought a thread gauge but I first just used a ruler to measure the pitch.

I ended up buying a tap for the internal thread. I did a lot of research about it and decided to just get the tap and be done with it.

Joe

I ended up buying a tap for the internal thread. I did a lot of research about it and decided to just get the tap and be done with it.

Joe

- Joined

- Mar 5, 2019

- Messages

- 216

Oh yeah that's great. I can't tell if I need a nut, although I imagine I do. I would probably order a tap as well

- Joined

- Feb 5, 2018

- Messages

- 638

Threading an internal acme thread has its difficulties from what I read. I was going to make a boring bar and try but it was another added step.

The acme taps aren't real cheap either. I found one that looked new in the package for $50.

Joe

The acme taps aren't real cheap either. I found one that looked new in the package for $50.

Joe