- Joined

- Dec 24, 2020

- Messages

- 1,042

@G-ManBart, I’d like to indulge your patience and explore a nuanced selection of cutting tools that I don’t understand well. This is drawing on your comment: “For that machine I would start out with something positive rake first.”

Quick recap, the lathe is an Enco 13x40 with Phase II BXA quick change. Additional info is that it is 1.5 HP, single phase and weighs in at a claimed ~1100 pounds w/o stand.

I am imagining a continuum of lathe properties where some range of these machines can be binned as “start with positive rake” and others as “use zero or negative rake”. In that continuum, which properties are of key importance? Is it HP and weight? And, of course, where does my machine sit in that space?

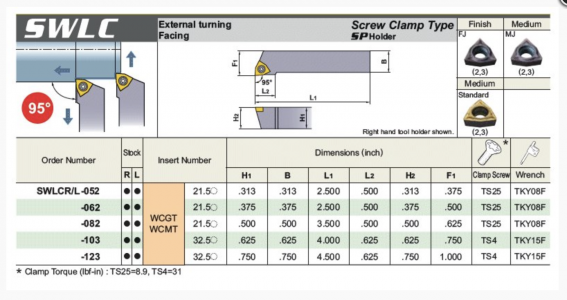

Next, and again in the context of my machine. Up to this time I have been using hand ground HSS. I have not found rake specified for inserts in the manner it is defined for ground HSS . Rake must be built into the chip breaker in some fashion? Can you educate me here? I see clearance or relief angle on the insert and that you suggest “C” which is a 7deg relief. The inserts I bought are “N”, or 0deg relief. I have never used 0deg relief before, is this an error with my machine?

Here are links I have used in this note:

Insert Designation Chart - provides ANSI and ISO designation code definitions for carbide insert shapes, relief angles, tolerances, chipbreaker codes, hole types, size values, thickness values, radius values, wiper lead angle, wiper clearance angle,

Carbide Insert Designation Chartwww.carbidedepot.com

Toolholder ANSI Designation Chart - provides ANSI and ISO designation code definitions for lathe toolholders for the insert holding type, insert shape, toolholder style, insert relief angle, direction, shank size, insert inscribed circle (IC), and

Toolholder ANSI Designation Chartwww.carbidedepot.com

The short version is that negative rake tools are stronger, but take more HP and rigidity to run well. Some, like the WMNG can be flipped because they have parallel sides, so you get twice the life out of them, which is a nice bonus, but probably shouldn't be a primary consideration for most people.

Your lathe is sort of in the middle for size/power, so it should be okay with negative rake inserts in some situations, but maybe not others. As an example, take the WMNG inserts you mentioned. A common size would be 432 or 332 inserts (same profile, different sizes) and those have a tip radius of 1/32, so .03125". The normal rule is that you want a DOC to be equal to the tip radius (1/2 is about the minimum). The negative rake increases tool pressure (work is coming down on it) and you're starting out at a pretty deep cut for most hobby machines....that can lead to chatter. Backing off on the DOC can lead to poor surface finishes because the tool is bouncing or smearing and isn't stabilized in the cut. The first thing I would try there would be a 431/331 insert with a 1/64 radius to see if it helps (and having both tip radius is probably smart anyway).

I use negative rake tools (CNMG) on my 13" lathe for roughing, and it's fine, but if I want to get a really nice finish I switch to something positive rake like the CCMT. I went with CNMG for that because they've very strong, extremely common and you can usually find deals on them even really good brand name inserts if you keep an eye on the folks selling inserts on eBay from business closeouts. I can often get a pretty decent finish by playing around with speeds and feeds, but it's definitely just okay, never great.

To add visuals, I took a picture of an MCLN tool that uses CNMG inserts (negative rake) and added a line showing how the top is angled down towards the front...there's your negative rake. I did the same with an SCLC tool that uses CCMT inserts with a positive rake. The positive rake means the CCMT insert has to be tapered from top to bottom for clearance, so they can't be flipped.

As far as tool and holder size, the standard BXA 250-201 and 202 will hold 5/8" tools. The 250-201-XL and 250-202-XL will hold 3/4" tools. The difference between 201 and 202 is that 202 has a grove in the bottom for using round tools like boring bars.