-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuck chuck.

- Thread starter rwdenney

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,334

If I know I'm going to be doing some heavy interrupted cutting I pull off the chuck and put some extra lube on the spindle threads

- Joined

- Aug 30, 2021

- Messages

- 37

I love the internet. I am all about the laziest method available!Lock the spindle with your strap wrench and chuck up a 6' 2x4 in the 4 jaw so it sticks out towards the front. Hang as much weight as you can on the end of the 2x4 without tipping the lathe over and turn the lights off for the night. The weight should only be a foot or less above the floor, the constant torque will break it loose while you're sleeping.

Also next time try some anti-seize on the threads. You can’t use enough in the shop. Squirt it everywhere.

- Joined

- Jan 1, 2018

- Messages

- 1,163

Anti-seize on lathe chuck threads? Is this generally accepted as a good idea?

I have a South Bend 13 and I have never swapped the 3 jaw to the 4 jaw. I always wondered about using anti-seize but didn't know if it was a good idea or not?

I have a South Bend 13 and I have never swapped the 3 jaw to the 4 jaw. I always wondered about using anti-seize but didn't know if it was a good idea or not?

- Joined

- Aug 30, 2021

- Messages

- 37

I haven’t died yet! I’m thinking a bit of anti-seize slathered around is better compared to hitting your lathe so hard you break gear teeth or the castings? Or hammering your precision spindle and bearings with a violent, (multi-felony/ex-con prolly too) impact gun?Anti-seize on lathe chuck threads? Is this generally accepted as a good idea?

I have a South Bend 13 and I have never swapped the 3 jaw to the 4 jaw. I always wondered about using anti-seize but didn't know if it was a good idea or not?

I wouldn’t spin it backward and try to cut if your chuck doesn’t have a set screw or lock collar but otherwise I approve of this method.

- Joined

- May 7, 2023

- Messages

- 1,399

I think putting antiseize everywhere is good if you want antiseize everywhere.Anti-seize on lathe chuck threads? Is this generally accepted as a good idea?

I have a South Bend 13 and I have never swapped the 3 jaw to the 4 jaw. I always wondered about using anti-seize but didn't know if it was a good idea or not?

Imo it would just collect chips and grit long term.

- Joined

- Aug 6, 2015

- Messages

- 3,894

I just look at the bottle of antiseize and it gets everywhere... there is some kind of dark magic in that product.I think putting antiseize everywhere is good if you want antiseize everywhere.

Imo it would just collect chips and grit long term.

But I do place a little bit on my 9x20 and Logan. A little bit goes a long way... by that I mean that I am still cleaning antiseize in Ocala when I applied this in Orlando... sob...

Last edited:

If I'm installing suspension bolts and tire lugs on my 50-year-old motorhome, anti-sieze is a requirement for me and I go through pounds of the stuff.

But screw-on chucks are a problem: I want them to be tight when installed but to come off easily. I don't want stopping the lathe to cause the chuck to unscrew itself, for example.

The method that I was most intrigued to read about was chucking up a long bar and hanging a weight on the end of it to let gravity perform its gradual work. I'd have never thought of that, but it is herewith now in the bag o' tricks.

I doubt that any internal friction clamp would hold the spindle tightly enough for the force I was applying.

The plastic bull-gear lock is a good idea but it needs execution that would actually work.

It would need to be made from steel and have a slightly modified tooth pattern to bite the teeth on the bull gear at their base instead of out on the tip. The plastic one is so weak that deflects and pops off with the slightest torque.

I'm not really interested in pounding the chuck in the other direction with an impact wrench. The mass of the chuck (about 80 pounds) would mean that the jaws would take most of the pounding rather than applying it to the spindle threads. My chucks are already old.

Next time I face this, the bar with a bucket of heavy scrap hanging off the end while resting gently with the back gears locking the spindle will be my backup plan. I don't want to make a habit of what worked on this occasion. But I suspect the 24-inch-handle Reed strap wrench is going to be a game-changer, too.

Rick "and that is due to arrive tomorrow or Thursday" Denney

But screw-on chucks are a problem: I want them to be tight when installed but to come off easily. I don't want stopping the lathe to cause the chuck to unscrew itself, for example.

The method that I was most intrigued to read about was chucking up a long bar and hanging a weight on the end of it to let gravity perform its gradual work. I'd have never thought of that, but it is herewith now in the bag o' tricks.

I doubt that any internal friction clamp would hold the spindle tightly enough for the force I was applying.

The plastic bull-gear lock is a good idea but it needs execution that would actually work.

It would need to be made from steel and have a slightly modified tooth pattern to bite the teeth on the bull gear at their base instead of out on the tip. The plastic one is so weak that deflects and pops off with the slightest torque.

I'm not really interested in pounding the chuck in the other direction with an impact wrench. The mass of the chuck (about 80 pounds) would mean that the jaws would take most of the pounding rather than applying it to the spindle threads. My chucks are already old.

Next time I face this, the bar with a bucket of heavy scrap hanging off the end while resting gently with the back gears locking the spindle will be my backup plan. I don't want to make a habit of what worked on this occasion. But I suspect the 24-inch-handle Reed strap wrench is going to be a game-changer, too.

Rick "and that is due to arrive tomorrow or Thursday" Denney

- Joined

- Mar 21, 2018

- Messages

- 1,598

The problem that I have with any strap wrenches around the pulleys, is that the pulleys are just thin cast iron. I fear that too much torque applied to one of them could break it off.

Since using the parchment paper washers, I haven't had a stuck chuck. If I ever do have another stuck chuck, I'll use my spindle crank to lock the spindle.

Since using the parchment paper washers, I haven't had a stuck chuck. If I ever do have another stuck chuck, I'll use my spindle crank to lock the spindle.

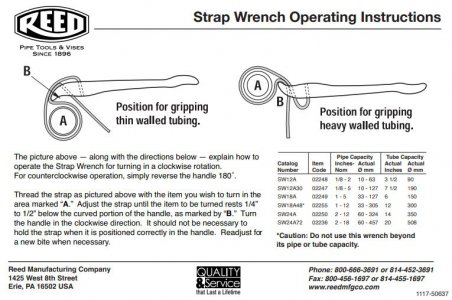

Yes, but the beauty of proper strap wrenches is that they are made for thin tubing. The Reed, for example, has two user modes:The problem that I have with any strap wrenches around the pulleys, is that the pulleys are just thin cast iron. I fear that too much torque applied to one of them could break it off.

Since using the parchment paper washers, I haven't had a stuck chuck. If I ever do have another stuck chuck, I'll use my spindle crank to lock the spindle.

The Titan that I broke could only be used in the "heavy-walled tubing" mode from above, and it shattered before doing any damage to the cone.

South Bend says to simply pull the belt after blocking the chuck against the ways with a piece of wood. The pictures are all for lathes driven from an overhead line shaft, so not much help with under-mount motors. Later editions of "How To Run A Lathe" suggested just grabbing the large belt pulley with the back gears enabled, again with the chuck blocked against the ways with a piece of wood. Uh, yeah. The strap wrench is just a better way to grab the pulley. Interesting that they use the back gears for that, but then I'm assuming that their world admit the possibility of a stuck chuck.

Rick "welcome to 1946" Denney