- Joined

- Dec 30, 2014

- Messages

- 259

Mzayd3,

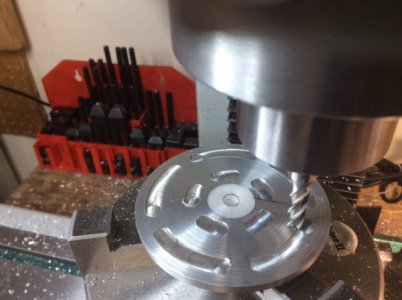

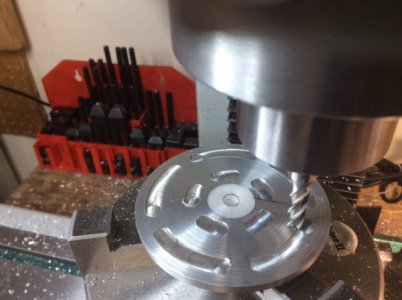

Thanks for the math! Is the formula for circumference 2 pi R? I think you left out the 2? And, I don't see and understand how to calculate the offset needed for the starting position of the inside circumference? As you can see in the photo of my sample, I started with the outside circ. I simply zeroed the RT and plunged at the start of the first arc. But as anyone who has worked thru this or looked at a cad drawing of it knows, you can't start the inside also at zero, there is a required adjustment to align the corners so the spokes are square to the center of the wheel.

I wanted to see how it was going to look, so I drew on the part to line up the edges and positioned the end mill and then read the degrees from the RT. I think this turned out to be about 14 degrees? I need a hint here for this value. Is must be related to the degrees of rotation of the cutter at the outside radius?

My next question is about making the side cuts Long the spokes. Is this just a simple offset of the Y axis?

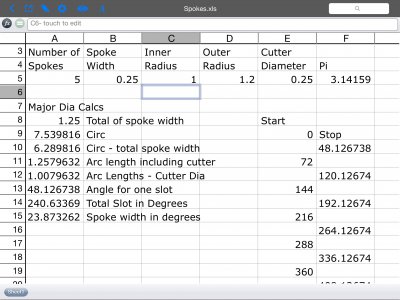

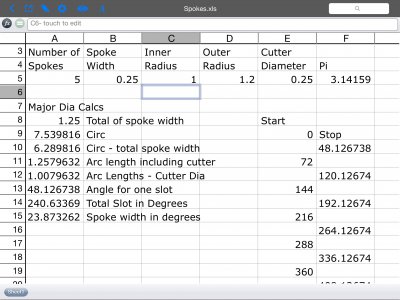

I spent several hours this morning doing the math and creating a spreadsheet.

Thanks again to everyone in this thread and the other thread about spokes!

Jim

Thanks for the math! Is the formula for circumference 2 pi R? I think you left out the 2? And, I don't see and understand how to calculate the offset needed for the starting position of the inside circumference? As you can see in the photo of my sample, I started with the outside circ. I simply zeroed the RT and plunged at the start of the first arc. But as anyone who has worked thru this or looked at a cad drawing of it knows, you can't start the inside also at zero, there is a required adjustment to align the corners so the spokes are square to the center of the wheel.

I wanted to see how it was going to look, so I drew on the part to line up the edges and positioned the end mill and then read the degrees from the RT. I think this turned out to be about 14 degrees? I need a hint here for this value. Is must be related to the degrees of rotation of the cutter at the outside radius?

My next question is about making the side cuts Long the spokes. Is this just a simple offset of the Y axis?

I spent several hours this morning doing the math and creating a spreadsheet.

Thanks again to everyone in this thread and the other thread about spokes!

Jim