- Joined

- Dec 30, 2014

- Messages

- 259

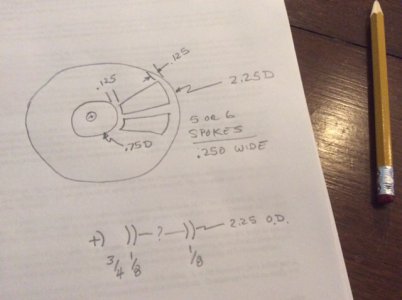

I found the recent post on making a four spoke hand wheel. That helped a bunch but I think I need some help from one of you CAD types.

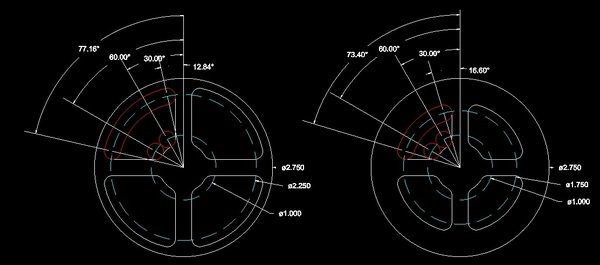

The drawing the Wreck made sense but I think since my dimensions are a bit different I need different starting and stoping angles?

My pulley wheels are 2.25 OD and have a 3/4" hub in the center. On my testing, it looks to me like a 1/4" end mill at .525" from center is about right for the start of the inner radial slot. And, I moved out to .800" and that looked good for the outside.

The thru hole is the test hole I did just to see what I didn't know about this! I really would like to do five or six spokes, but I am game to start with four.

Thanks,

Jim

The drawing the Wreck made sense but I think since my dimensions are a bit different I need different starting and stoping angles?

My pulley wheels are 2.25 OD and have a 3/4" hub in the center. On my testing, it looks to me like a 1/4" end mill at .525" from center is about right for the start of the inner radial slot. And, I moved out to .800" and that looked good for the outside.

The thru hole is the test hole I did just to see what I didn't know about this! I really would like to do five or six spokes, but I am game to start with four.

Thanks,

Jim