-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spindle wrench

- Thread starter DavidR8

- Start date

- Joined

- Oct 16, 2019

- Messages

- 6,596

That’s the ticket Frank!

Any idea how they ar measured?

Top of the spline?

Edit: seems that they are measured from spline to spline. I’ll see if I can get a caliper in to take a measurement.

Maybe Westen Supply would carry or bring one in.

Sent from my iPhone using Tapatalk

Any idea how they ar measured?

Top of the spline?

Edit: seems that they are measured from spline to spline. I’ll see if I can get a caliper in to take a measurement.

Maybe Westen Supply would carry or bring one in.

Sent from my iPhone using Tapatalk

Last edited:

- Joined

- Nov 27, 2012

- Messages

- 7,864

I remember now, search for PTO coupler or adapter. Can buy em on ebay. They're used on tractors to drive external accessories or something. PTO stands for Power Take Off. Anyone correct me if I'm wrong, I don't know anything about tractors.

BTW ToT has a video on how he machined a PTO sline, the male drive though.

Edit: n/m Frank beat me to it, I type slow.

BTW ToT has a video on how he machined a PTO sline, the male drive though.

Edit: n/m Frank beat me to it, I type slow.

- Joined

- Oct 31, 2016

- Messages

- 2,649

Since you have a MT3 spindle there should be a slot in the quill when it is all the way down to allow you to remove whatever you have in the quill. My Wilton Drill Press has this setup Here's a picture for you. You might have to rotate the spindle to see it.

There is a special key shown in the RF30 manual to remove what is in the quill.

There is a special key shown in the RF30 manual to remove what is in the quill.

Attachments

Last edited:

- Joined

- Nov 27, 2012

- Messages

- 7,864

Making one will give me a chance to try the bolt circle function on my DRO

Sent from my iPhone using Tapatalk

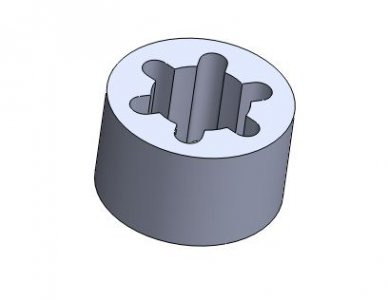

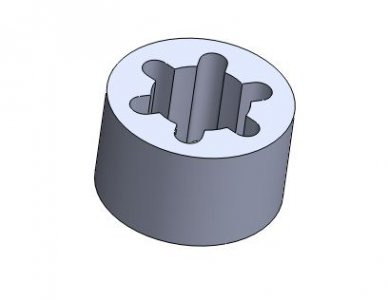

You can find the plans online on how to make one of the wrenches. It'll show you the dimensions you need to make it just by drilling holes. No broaching needed.

- Joined

- Nov 27, 2012

- Messages

- 7,864

Since you have a MT3 spindle there should be a slot in the quill when it is all the way down to allow you to remove whatever you have in the quill. My Wilton Drill Press has this setup Here's a picture for you. You might have to rotate the quill to see it.

View attachment 315735

There is a special key shown in the RF30 manual to remove what is in the quill.

The wrench talked about here is for holding to spindle to tighten/loosen the draw bar on a mill/drill.

But guys with RF-30/31s usually just pinch the belt to hold the spindle. On my gearhead mill I would just switch to low gear. But I have a Spindle Stop now that engages the spline with a pin.

- Joined

- Nov 27, 2012

- Messages

- 7,864

You can find the plans online on how to make one of the wrenches. It'll show you the dimensions you need to make it just by drilling holes. No broaching needed.

Well wadda ya know. Quick search came up with this thread here. Check post #4 by @RJSakowski

What size spline wrench for spindle rf31?

What is the size of the splinewrench needed to hold the spindle while loosening the drawbar? 28mm? Where is a source to buy one?

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Feb 1, 2015

- Messages

- 9,645

I made a spindle wrench to fit the G0755 mill and multiple others. A socket could be made to fit and a handle screwed or welded to it. A flange could be added to make mounting the handle easier.

Looking at your photo, there is not a lot of thread engagement of the spindle nut. Was the pulley modified?

Re, the spline couplers for tractors, PTO splines are either 1-1/8" or 1-3/8". The 1-1/8 coupling may work for you.

Looking at your photo, there is not a lot of thread engagement of the spindle nut. Was the pulley modified?

Re, the spline couplers for tractors, PTO splines are either 1-1/8" or 1-3/8". The 1-1/8 coupling may work for you.

- Joined

- Oct 16, 2019

- Messages

- 6,596

I don’t believe it was modified @RJSakowski. If it was, the modifications are not apparent to me.

I have some 10L that I might try using to make a socket similar to the drawing in your post above.

Sent from my iPhone using Tapatalk

I have some 10L that I might try using to make a socket similar to the drawing in your post above.

Sent from my iPhone using Tapatalk