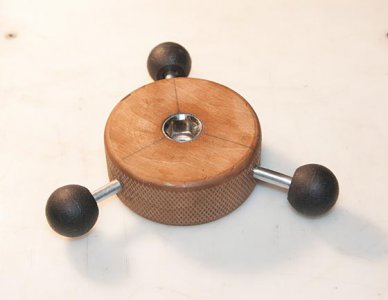

Mine is a revolving handle. The knob rotates independant of the rest of the handle.

The fastener is a shoulder screw. I'd post a pic of what a shoulder screw is, but I'm on a smartphone and have no idea how to do that. There was a time when I could right click, find "properties", then copy the URL. Seems the stopped that on phones.

The screw has a 2" unthreaded shank. My knob has a countersunk end only to enclose the shoulder screw head, but the countersink is .01 larger in diameter than the shoulder screw head. The knobs smaller diameter inside bore is .5" diameter and 1.99 long. The shoulder screws bearing shank is 2" long and .495" diameter. The knob, installed with 1 drop of grease on the shoulder screws shank, spins like it on ball bearings.

But, it is absolutely, a revolving knob. Rather smooth turning too I might add