Only when someone catches you!

Definitely not going there! Kitchen is to have planned makeover anyway, but even so ..

Serendipity ??

I happen to have 2 x 7kg butane gas cylinders + regulator left over from when old

chez caravan, purchased as already 2nd-hand in 1998 finally reached a condition where it had to be disposed of in 2018. One cylinder is full, the other about half-full. It seems natural to have them be useful again. Then I compare the cost of a eBay gas hob to the cost of variously, a ACME tap, a replacement nut, some fire bricks, etc.

Looky here!!

So I clicked "Buy it now". The HM collection of rabbit-holes has now led me into (partial) heat treating. This gas hob, with some

ad-hoc modification on top to contain and connect to the compound, becomes a major resource not subject to censure for sneaking time on the kitchen cooker. Also, it is acquired at the price of doing single point ACME threading (sans tap) learning curve.

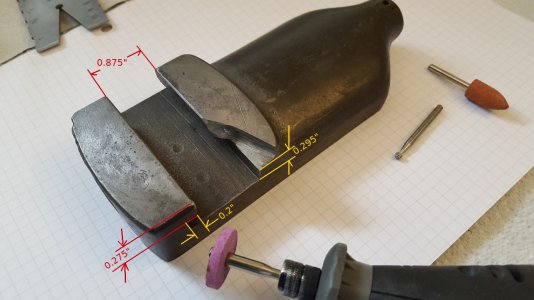

I will probably expend a good deal more than that practicing both the weld, and making ACME threads.

Now also, I am bounced into reading Machinery's Handbook to discover what are class 3B threads, because it begged the question..

"What other classes are there"? Must so stop with the distractions!