-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Bend 9 C Lathe Restoration

- Thread starter LX Kid

- Start date

- Joined

- May 26, 2015

- Messages

- 762

"Maybe" I'm missing something inside the handle that is letting it flop down. If that's the case I could drill and tap the top of the rod pivot so it not drop down. Even at that though the handle would be pushed upward and not tighten belt. Have to play around with it cause I really don't want the spring that I added.

- Joined

- May 26, 2015

- Messages

- 762

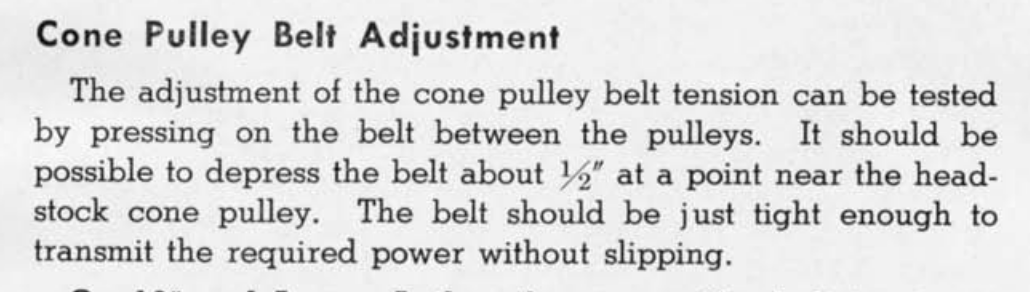

Yeaaaaaaa! I had the turnbuckle turned around the wrong way. I switched ends and "shazam" the belt tightens like it should. Thank you Brino very much for the help. " No one said I had to be smart just willing!" How much belt deflection is recommended?

Attachments

- Joined

- May 26, 2015

- Messages

- 762

My apology sir! Thank you so much for your help! I've gotten a lot of help and advice here and sometimes an old fart get mixed up. ( Most of the time.) LoL Thanks again for pulling my bacon out of the fire.

- Joined

- May 26, 2015

- Messages

- 762

After the receipt of my new shorter flat belt, I'm thinking this restoration is a done deal! My next project is a SB 9 A which should be here next week from Illinois. It was the 9A model that I really wanted because of the change gearbox, the taper attachment and powered cross feed. This 9C gave me a first time taste of what's to come as I believe the 9A is going to be a lot more challenging. The 9A has no counter-shaft assembly and is powered by 1/2" belt pulley's attached to the motor and the spindle (looks welded to spindle). I'll be in pretty deep on this one so I'll have to keep it. (And really want to anyway!)

- Joined

- Oct 16, 2019

- Messages

- 6,576

Interesting way to drive it. Lots of additional strain on the spindle bearings not to mention the loss of spindle bore.After the receipt of my new shorter flat belt, I'm thinking this restoration is a done deal! My next project is a SB 9 A which should be here next week from Illinois. It was the 9A model that I really wanted because of the change gearbox, the taper attachment and powered cross feed. This 9C gave me a first time taste of what's to come as I believe the 9A is going to be a lot more challenging. The 9A has no counter-shaft assembly and is powered by 1/2" belt pulley's attached to the motor and the spindle (looks welded to spindle). I'll be in pretty deep on this one so I'll have to keep it. (And really want to anyway!)

Are you getting a good deal?