Well, I'm no expert but I have a few theories:Edit: I am confused as to how a feed shaft "develops" a bow in it...

1) If the shaft was maybe something like cold rolled with forming skin tension or whatever you call it, then cutting the key slot down the whole length might allow stress relief & curl over time? Maybe 'good' shafts are post stabilized or start with different material? One would think it should be a natural bow, but in my case where it starts rubbing, its being constrained by the carriage worm bracket itself.

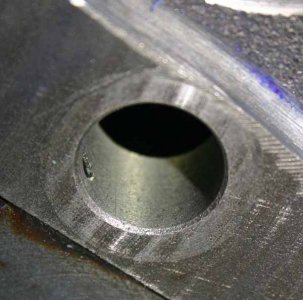

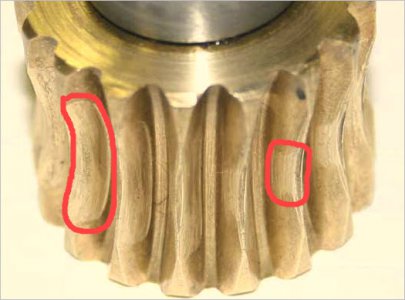

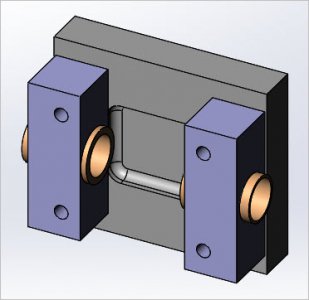

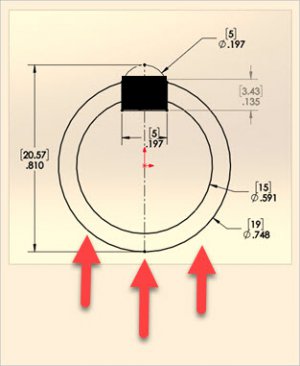

2) A bad worm/bracket design where the thrust force starts to erode the CI bracket by power traversing over time. If things get out of alignment, maybe puts wonky force to the shaft & gets distorted. You can see my fix which has yet to be trialed, milled out the bracket slightly & inserted a bronze wear ring. I have a better plan, but first need to get this resolved & lathe back together. (This is exactly what Keith Fenner remedied on his lathe too, but he silver soldered the ring on).

3) Some lathe mover slipped a strap under my bar when I wasn't looking, haha. (That explains the first problem I had with poor surface finish when lathe was new, I actually cant recall if shaft was straightened at the time or bent back. But that doesn't explain many years of happy turning so I suspect 1. or 2.

Last edited: