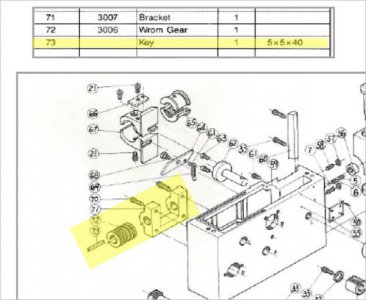

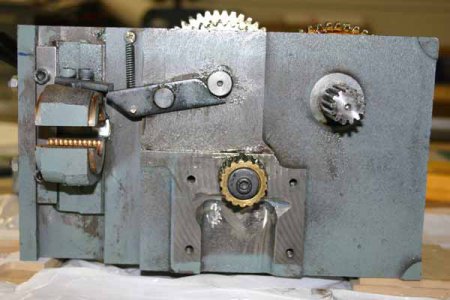

I have determined that the power feed shaft on my Taiwan 14x40 lathe has developed a bow that is causing friction in the driveline to the extent the clutch is complaining. Mainly around the worm gear bracket I think. I'm in the process of getting it straightened, but it was maybe not great quality to begin with so thinking about a backup plan.

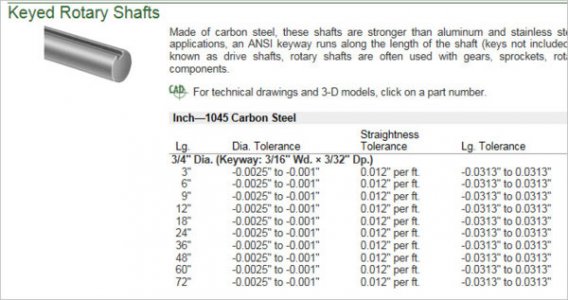

It is 19mm OD (0.748") x 1372mm length (54.0") with a 5mm key slot (0.197"). The tailstock end is reduced to 15mm for bearing & keyway terminates just short, but that can be worked around with continuous keyed stock. I considered a 3/4" nominal shaft which is more common, but I have to confirm what OD tolerances because it slides along a hardened worm gear with ID to accommodate the 19mm dimension (ie 0.750" +0.001 -0.000 shaft likely too tight for worm). Also they are typically 3/16" (0.188") slot so would have to be widened anyway.

I'm also chasing down possibility of retrofitting a new part off a similar lathe but that's still ongoing.

My measurements are maybe not the best but with ends constrained in the HS drive socket & TS bearing & just rotating by hand with a dial, I'm measuring max run-out from headstock to tailstock at roughly 6" increments like: 0.015", 0.025", 0.048", 0.050", 0.052", 0.050", 0.045", 0.027", 0.017".

Leads or advise welcome.

It is 19mm OD (0.748") x 1372mm length (54.0") with a 5mm key slot (0.197"). The tailstock end is reduced to 15mm for bearing & keyway terminates just short, but that can be worked around with continuous keyed stock. I considered a 3/4" nominal shaft which is more common, but I have to confirm what OD tolerances because it slides along a hardened worm gear with ID to accommodate the 19mm dimension (ie 0.750" +0.001 -0.000 shaft likely too tight for worm). Also they are typically 3/16" (0.188") slot so would have to be widened anyway.

I'm also chasing down possibility of retrofitting a new part off a similar lathe but that's still ongoing.

My measurements are maybe not the best but with ends constrained in the HS drive socket & TS bearing & just rotating by hand with a dial, I'm measuring max run-out from headstock to tailstock at roughly 6" increments like: 0.015", 0.025", 0.048", 0.050", 0.052", 0.050", 0.045", 0.027", 0.017".

Leads or advise welcome.