-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Slitting saw arbor types

- Thread starter ericc

- Start date

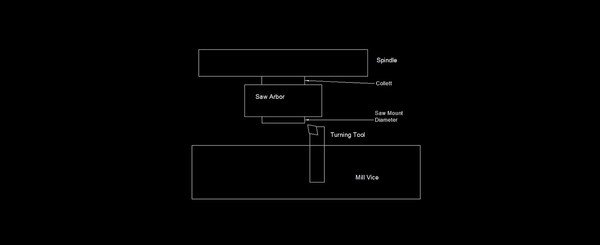

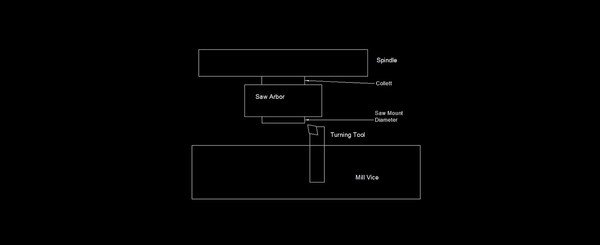

Wreck Wreck,If you truly desire accuracy rough the arbor and tap the saw mounting end beforehand, install in mill spindle, place a lathe turning tool in the vise and turn the saw bore diameter in place in the spindle of the mill, this will have to be done every time so you will only use each arbor once, much like dressing a grinding wheel, Works a charm.

Can you explain this further?

What do you mean when you say, 'every time so you will only can use the arbor once'.

- Joined

- Jul 2, 2014

- Messages

- 7,594

Not Wreck here, but it is re-truing the tool each time it is used to avoid the inaccuracies in the spindle, collet, and arbor shank. It is like making a dead center for the lathe in a three jaw chuck. When you machine it in place, it is true to the lathe center line axis. If you take the center out of the chuck, and then re-install it, it will not run true. If you make an slitting saw arbor with a deep thread for the screw, you can keep re-truing the mounting face and shoulder each time you install it, and it will be dead nuts true every time. Great idea!

- Joined

- Sep 29, 2014

- Messages

- 2,102

What he said, use the mill spindle like a lathe spindle and turn the arbor in place.

- Joined

- Sep 29, 2014

- Messages

- 2,102

A 6" vise is overkill for a RF45 style mill. A 4" is more appropiate for that size mill & IMO 5" max. I have a 5" GMT vise on my PM45 & it's slightly too big. Not enough Y axis travel to make use of the 5" full capacity. Better to save your money rather than getting something too big & most importantly the weight. I take my vise of the table quite often, a 6" is still light enough for me to be carried by hand but I'm glad I have a 5". I also have a 4" vise as well. I prefer the 5" though.

But those GMT 6" Premium vises are pretty nice. I'd love to have one but don't need one on my current mill. But if you plan on upgrading to a full size knee mill in the future than the 6" will be perfect.

Here's what the 5" looks like on my mill.

I couldn't even complete this cut without my bellows & DRO scale getting in the way. Not enough Y travel & the 5" vise is not even maxed out.

Here's what a 6" vise looks like on another PM45 (gt40's)

View attachment 253544

But those GMT 6" Premium vises are pretty nice. I'd love to have one but don't need one on my current mill. But if you plan on upgrading to a full size knee mill in the future than the 6" will be perfect.

Here's what the 5" looks like on my mill.

I couldn't even complete this cut without my bellows & DRO scale getting in the way. Not enough Y travel & the 5" vise is not even maxed out.

Here's what a 6" vise looks like on another PM45 (gt40's)

View attachment 253544

- Joined

- Apr 26, 2015

- Messages

- 135

For the people that have the import style arbor and the blades are stuck on, they can be removed by turning the cap instead of the screw. I have undone several for friends. If you aren't worried about marring the cap just have at it with a pipe wrench. If you don't want to damage it then bore a hole in a piece of scrap with then same id your cap has. Split one side then drill and tap for a pinch bolt. Once secure use the pipe wrench to unscrew the cap or make a handle for the tool if you think you will need it often. I like the arbors that Stephan made in his video.

Hello, my name is Brian and I'm a toolaholic!

Hello, my name is Brian and I'm a toolaholic!

Dan_S, (and anyone else who might know)

In the Stefan Gotteswinter's videos, he mentions using a graded bolt as the arbor's raw material. I didn't catch specifically which grade he was using.

My question: assume I 'm using a SAE Grade 8 bolt. This would have to be annealed before machining, then re-hardened and tempered, right?

Thanks,

Greg

In the Stefan Gotteswinter's videos, he mentions using a graded bolt as the arbor's raw material. I didn't catch specifically which grade he was using.

My question: assume I 'm using a SAE Grade 8 bolt. This would have to be annealed before machining, then re-hardened and tempered, right?

Thanks,

Greg

![thumbnail_IMG_20170304_173156797[1].jpg thumbnail_IMG_20170304_173156797[1].jpg](https://www.hobby-machinist.com/data/attachments/185/185420-e61329ebf5cac0d43d1e116e6d34f03f.jpg)

![thumbnail_IMG_20170304_173432137[1].jpg thumbnail_IMG_20170304_173432137[1].jpg](https://www.hobby-machinist.com/data/attachments/185/185421-3bbf131d641c48c842547521ebcb9f05.jpg)