- Joined

- Nov 5, 2016

- Messages

- 1,419

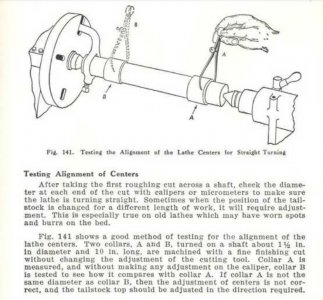

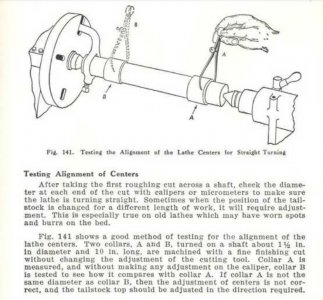

If you're still getting a taper between centers, here's a section out of South Bend's "How to Run a Lathe" on doing a two collar test and instructing to align your tail stock if getting a taper. Have you already tried this? You should be able to remove the taper and turn true between centers by properly adjusting your tail stock. At least get it pretty close, not 0.022" off...

Use mics though, not calipers.

Ted

Use mics though, not calipers.

Ted