- Joined

- Jan 28, 2012

- Messages

- 27

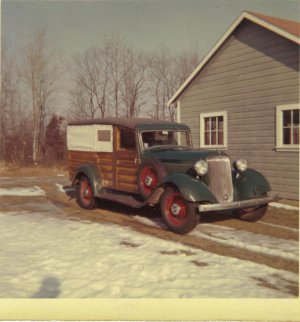

I have a mid 40's Dodge truck actually more than 1 and I am on strict orders not to buy any more.

i wonder if she will believe me when I tell her some one gave it to me .

Anyway these trucks have unique brake cylinders (to me at least). They have stepped cylinders ie different diameters for each side. Some of these are now impossible to find so I am looking to refurbish what I have. Google being my friend I did a search and found a thread on another machining forum which pretty much confused me. So some questions

1 is this something a newbie should even consider trying

2 would you hone or use a boring bar to upsize the bores for the sleeves

3 would you do this on a mill or a lathe

Thanks

Gord

i wonder if she will believe me when I tell her some one gave it to me .

Anyway these trucks have unique brake cylinders (to me at least). They have stepped cylinders ie different diameters for each side. Some of these are now impossible to find so I am looking to refurbish what I have. Google being my friend I did a search and found a thread on another machining forum which pretty much confused me. So some questions

1 is this something a newbie should even consider trying

2 would you hone or use a boring bar to upsize the bores for the sleeves

3 would you do this on a mill or a lathe

Thanks

Gord