- Joined

- Sep 8, 2019

- Messages

- 4,392

So right when I was about to change the gears to cut 20 TPI, my Dad stopped by so I had a helper. This was a super easy task. I will post pictures and cite the very few challenges that I faced.

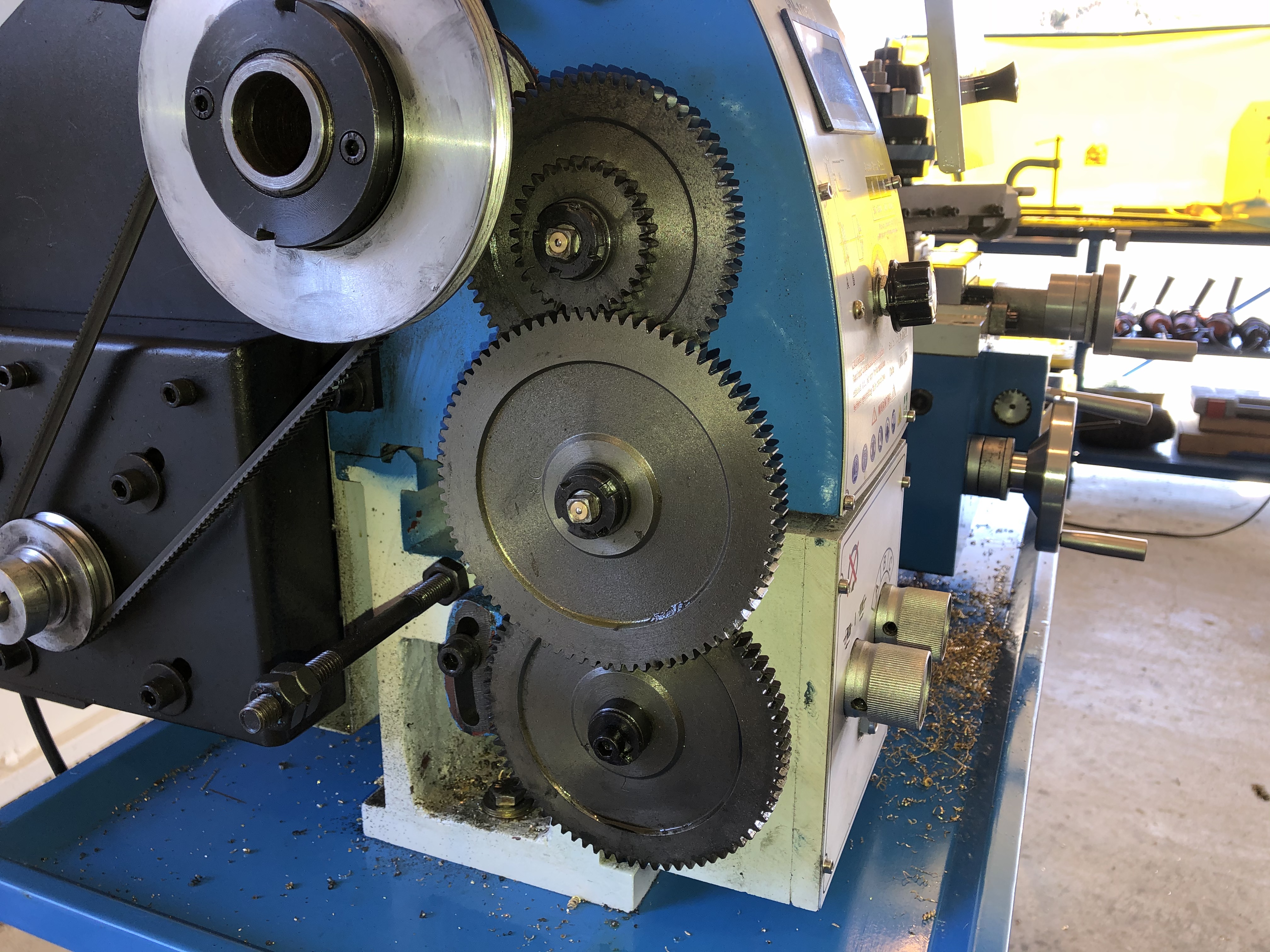

Here is the gear setup that came with the lathe: set up for turning, facing, boring, etc. (slow carriage and cross slide power feed speeds).

Here is the gear setup that came with the lathe: set up for turning, facing, boring, etc. (slow carriage and cross slide power feed speeds).