- Joined

- Dec 18, 2019

- Messages

- 6,464

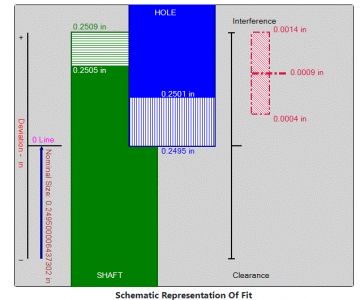

After reading through a few threads on the subject, and then consulting the Machinery's Handbook 17th Edition, I'm still confused about things. I have a 0.2495" 1144 steel pin, that I want to be permanently held by a piece of 0.300" thick 6061 aluminum. From what I understand, the hole in the aluminum should then be about 0.001" * 0.2495 or about 0.00025" smaller than the steel pin, at room temperature. Is this right? Sure would be more convenient if it was 0.0005" as reamers are available in 0.0005" steps. Can I use a 0.2490" reamer for the hole instead with 0.300" thick material? The aluminum piece is about 5/8" wide.

What I am confused about are the units of thermal expansion. For aluminum is it 13 micro-inches / degree F? And for steel, about 6.5 micro-inches / degree F? If I leave the steel pin at room temperature, let's call it 72F, and toss the aluminum in boiling water, then the hole diameter would increase by 13e-6 * (212-72) inches from the ambient diameter? (0.0018" larger?) If the hole started at 0.2490 at 72F, then it would be 0.2490 + 0.0018 = 0.2508" at 212F? So there would be 0.2508-0.2495 = 0.0013" diameter difference between the pin and the hole? I would probably put the aluminum in an oven and maybe heat it to 300F, for more clearance, but is my thinking correct on this? Seems like one won't have much time to pull this off! I have to set at least 6 pins, so I'd like a way to do this quickly and accurately.

If I am not thinking about this correctly, please let me know. I'm aware of other ways to get this done, but I'd really like to learn about shrink fitting a steel pin into aluminum in this thread.

What I am confused about are the units of thermal expansion. For aluminum is it 13 micro-inches / degree F? And for steel, about 6.5 micro-inches / degree F? If I leave the steel pin at room temperature, let's call it 72F, and toss the aluminum in boiling water, then the hole diameter would increase by 13e-6 * (212-72) inches from the ambient diameter? (0.0018" larger?) If the hole started at 0.2490 at 72F, then it would be 0.2490 + 0.0018 = 0.2508" at 212F? So there would be 0.2508-0.2495 = 0.0013" diameter difference between the pin and the hole? I would probably put the aluminum in an oven and maybe heat it to 300F, for more clearance, but is my thinking correct on this? Seems like one won't have much time to pull this off! I have to set at least 6 pins, so I'd like a way to do this quickly and accurately.

If I am not thinking about this correctly, please let me know. I'm aware of other ways to get this done, but I'd really like to learn about shrink fitting a steel pin into aluminum in this thread.