- Joined

- Feb 13, 2023

- Messages

- 62

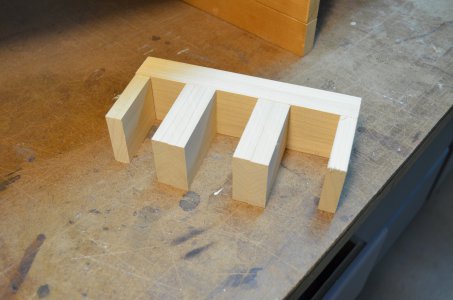

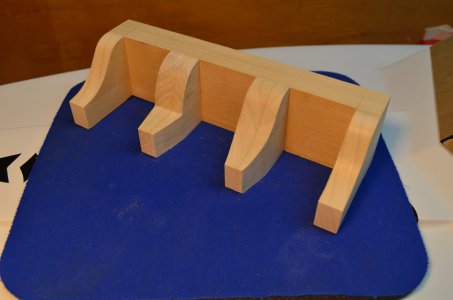

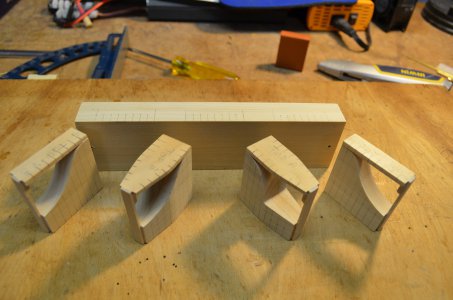

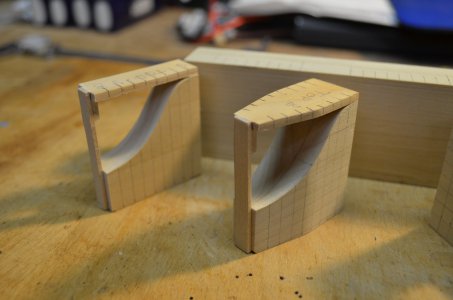

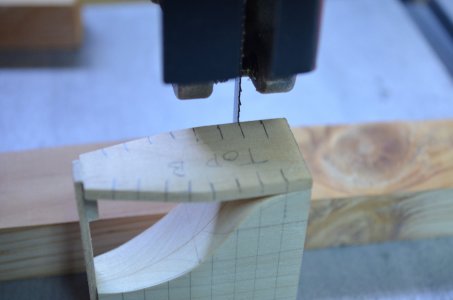

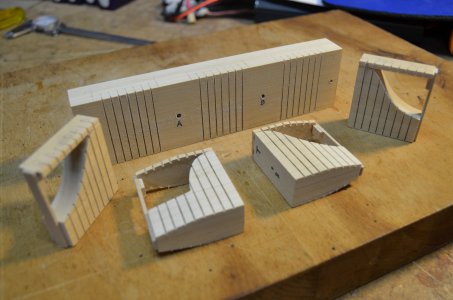

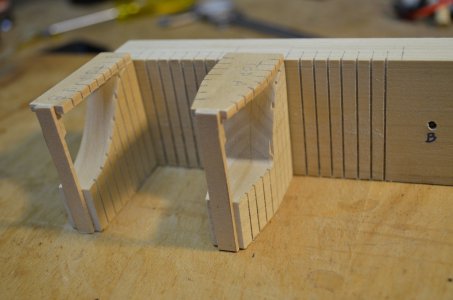

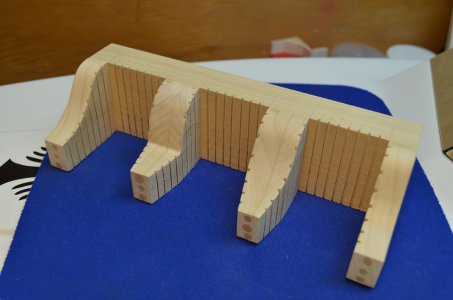

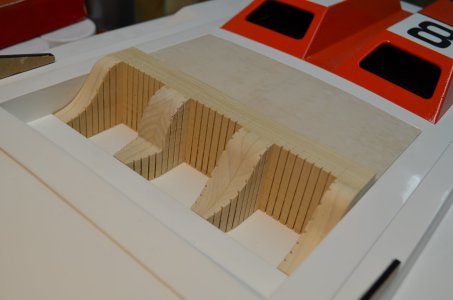

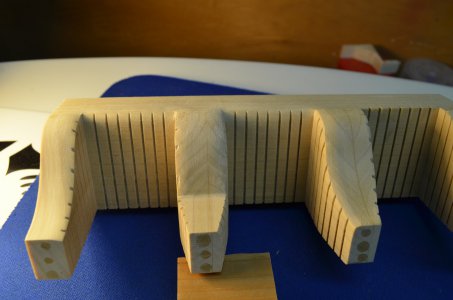

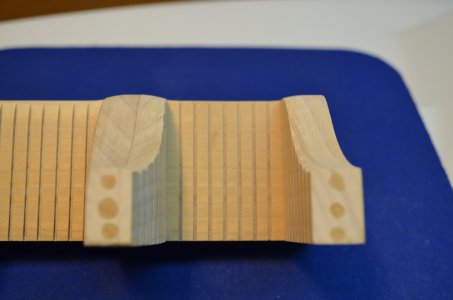

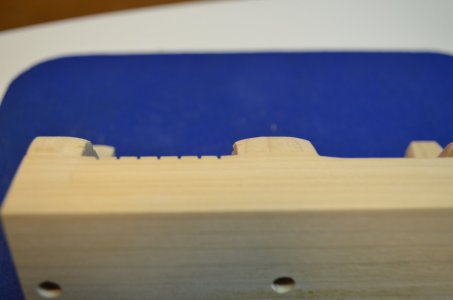

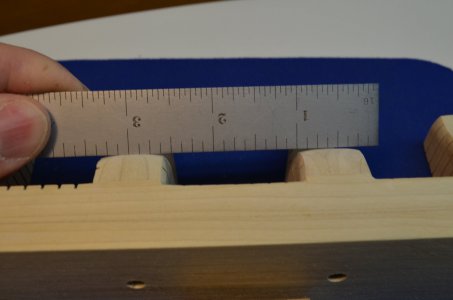

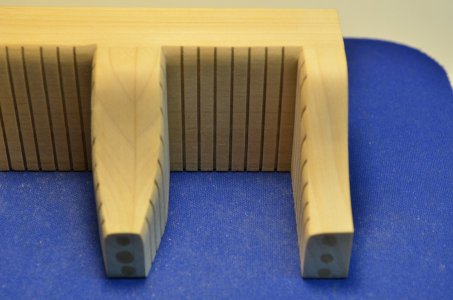

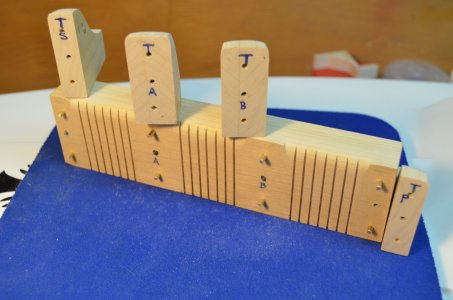

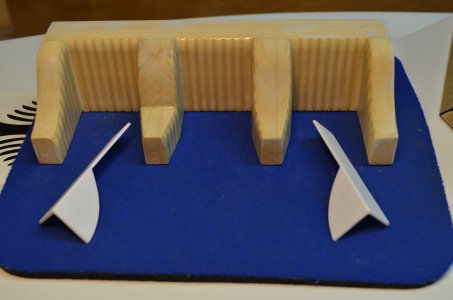

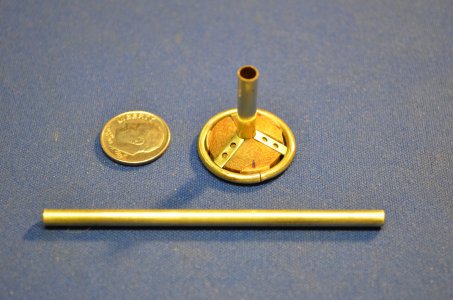

Since the boat is going to bounce around a lot, I had to hold down the cockpit cover somehow. They do make lock down screws for this purpose but then they stick out of the deck with a knurled grab you push and turn. I can't have that as they are unsightly and take away from the appearance. So I fashioned this hidden mechanism under the cockpit deck to hold it down. The rod sticks out into the cockpit behind the crew and is hidden by a hatch. The two piece of wood on the left engage the hatch coaming. They are beveled to keep constant pressure holding the hatch in place.