You guys are going to hate me....

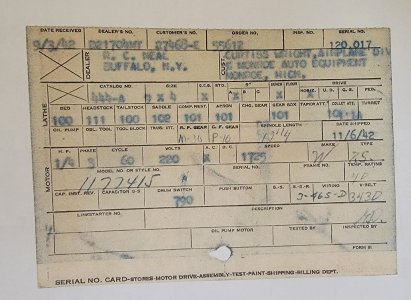

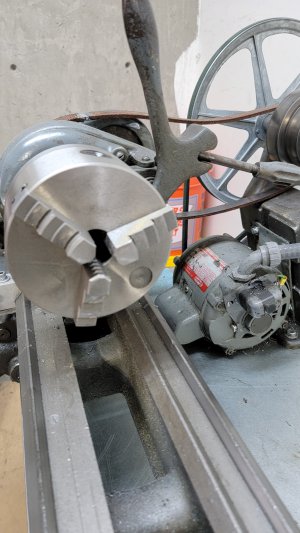

Got the lathe for $1000. Appeared to be in very good shape, in as far as I can tell. The machine is from 1942 (guy paid Grizzly to get the serial number card, see below). The lathe came with a well-organized notebook with every piece of information he could find, every receipt, contact, notes, everything. Apparently he bought it in 2014 for $1700 (with milling attachment, which came with it), not including the bench or any accessories. The leather belt looks to be in great shape, but didn't try to turn it on. Carriage is smooth, and there doesn't appear to be much wear on the bed that I could tell (hand-tighten nut @ headstock for barely free movement, move towards tailstock). Not a bit of rust ANYWHERE, this guy loved his tools!!

Aside from the lathe being a killer deal, they were getting rid of his other equipment for pennies on the dollar, mostly because they didn't know what most of the stuff was. I got brand new Huot indexes (fractional, number, and letter) for $2 each, for instance. Mostly everyone there was focused on his amassment of guns/ammo, and there was little attention paid to his machinary. In essence, I made out like a bandit, and it's been quite a while since I've done so well at one of these sales.

Now that you hate me, I need your help:

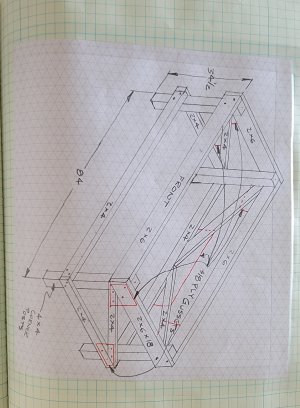

I need to make the lathe as light as possible in order to transport it. The bench itself weighs a ton, even with only the lathe on it. I've got a Johnson Bar and some dollies, but moving it is going to require some creativity. I am going to see about renting a truck with a lift gate, however I'm concerned that I won't be able to back it down close enough to help much (driveway is gravel), because the garage is after a bend in the driveway. I've got a new subaru outback and could rent a trailer, however getting it onto the trailer will be quite difficult I imagine, but at least I can park it right at the opening of the garage.

Here's the other problem: My driveway SUCKS -- it's paved, sure, but is extremely steep and angled at the top (UPS/USPS don't even try going up, if that gives you any indication). When I moved in to my house in October, it took an army of folks and lots of hurt backs to move my equipment in, and I am extremely worried about getting the lathe safely into my garage, while mitigating every possible risk. I can back a trailer up to my garage at the top, but can't go in (not tall enough), so I'll have to unhook it from the hitch and slowly lower it. I've done this before and am confident I can do it again. All this is justification for what I'm about to ask...

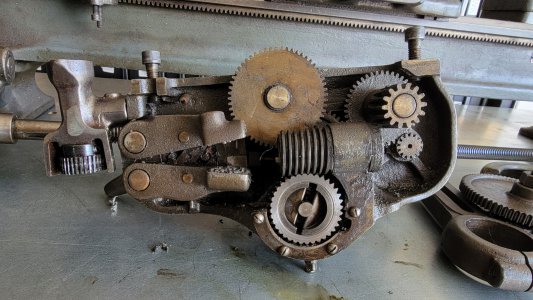

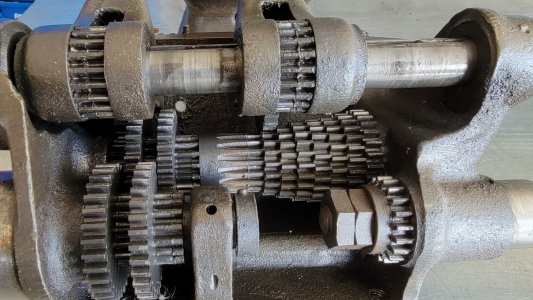

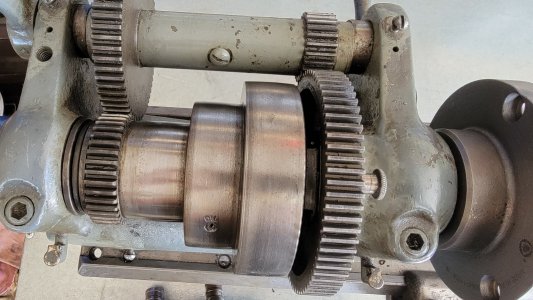

I would like to take as many things off from the lathe before moving it to make it easier to transport (and less top heavy). I've already removed the tailstock, and I can remove the 3-jaw chuck when I go back tomorrow. I'm looking to remove things that are possible to put back pretty straightforwardly, however I will say that I am very technologically/mechanically savvy, I just don't know anything about lathes. What I don't want to do is get myself into a pickle due to my ignorance. I'm not thinking of doing anything with the leadscrew, for instance, but I am thinking about the following:

1) Carriage/apron assembly

2) Motor/pulley assemblies

3) Gearbox

4) Anything in the headstock

I'm eager to hear whether or not any of these are a terrible idea, or if anyone has any advice on best practices/things to watch out for. I have the parts diagrams, which I will be studying this evening to better understand things. I'll see what I can find on the youtubes as well. I think that the best case scenario would be if I could light the lathe enough, I could get it in the back of my car, and just load the bench in the trailer.

Any advice, thoughts, or prayers would be deeply appreciated!

Cheers,

IHateMayonnaise

20210423_151123.jpg1.8 MB · Views: 49

20210423_151123.jpg1.8 MB · Views: 49 20210423_151210.jpg1.3 MB · Views: 47

20210423_151210.jpg1.3 MB · Views: 47 20210423_151228.jpg635.7 KB · Views: 41

20210423_151228.jpg635.7 KB · Views: 41 20210423_110637.jpg2.6 MB · Views: 37

20210423_110637.jpg2.6 MB · Views: 37 20210423_110725.jpg2.3 MB · Views: 36

20210423_110725.jpg2.3 MB · Views: 36 20210423_110749.jpg2.2 MB · Views: 34

20210423_110749.jpg2.2 MB · Views: 34 20210423_110759.jpg2.1 MB · Views: 41

20210423_110759.jpg2.1 MB · Views: 41 20210423_110804.jpg2.3 MB · Views: 36

20210423_110804.jpg2.3 MB · Views: 36 20210423_110807.jpg1.1 MB · Views: 38

20210423_110807.jpg1.1 MB · Views: 38 20210423_110813.jpg2.4 MB · Views: 39

20210423_110813.jpg2.4 MB · Views: 39 20210423_110820.jpg1.1 MB · Views: 46

20210423_110820.jpg1.1 MB · Views: 46