- Joined

- Sep 24, 2020

- Messages

- 1,907

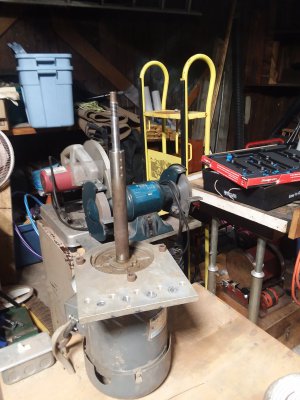

What is the preferred method to shorten the shaft on a motor ?

I have a 1/2 HP Marathon dual voltage I just got. Set-up as a redneck buffer, but may put it to better use.

Has a 1" shaft that has been turned down to 1/2" at the end.

There is 11 1/2" of shaft out of the body.

I have a 1/2 HP Marathon dual voltage I just got. Set-up as a redneck buffer, but may put it to better use.

Has a 1" shaft that has been turned down to 1/2" at the end.

There is 11 1/2" of shaft out of the body.