- Joined

- Sep 23, 2010

- Messages

- 619

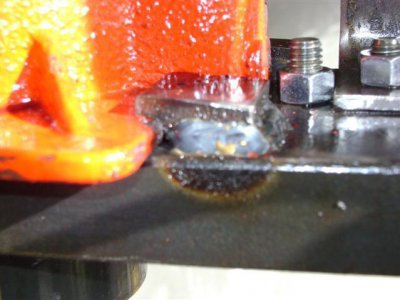

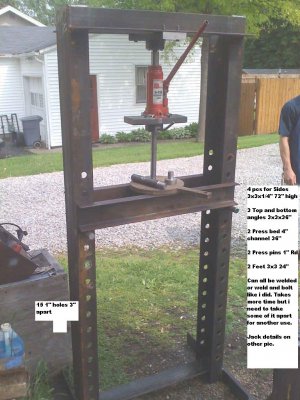

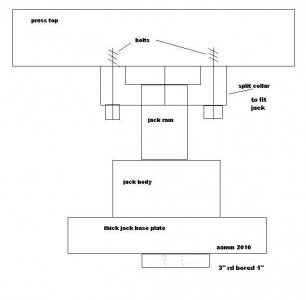

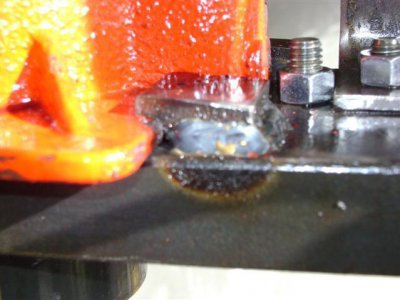

Here is a shop press project that has been ongoing for the last 17 years or so. I started it cutting and punching all the metal. Then i got side tracked with my train bridges so it sat for about 15 years in the corner. Then one night my daughter came home and said they wanted 80 bucks to press a new wheel bearing in her car. I jumped up and said wait a few hours i will do it. So i went to my lathe and made up the split block to hold the jack and proceded to weld up the frame. Then next day it was done. The orig 6T jack worked fine as long as my torch was handy to heat up some of the parts but i thought 12T would be better. I really didn't want to stress the frame with a 20T since the reason i started this press i forgot long ago. So move ahead 2 years i had bought a 12T jack and had the split blocks made to hold it to the top of the press i just needed to swap it all out. Since this was a long weekend and its too cold to feed the fish i headed to the garage. Just had to drill some new mounting holes and make some clamps with my shaper to hold the base of the jack to the plate and its done again. Now i am working on some more quick change tooling for smaller shafts since i am doing some bearing salvage. More pics of that to come.

Another feature of this press is its going to double as a hoist frame to lift my 2 bigger lathes on their feet. The press bed and bottom plate are bolted in so i can remove them with the jack. Then i can straddle my lathe bed and with a 1/2T chain hoist attached to the top of the press frame i can safely lift my heavy parts. Enjoy. ???? just ask...Bob

Another feature of this press is its going to double as a hoist frame to lift my 2 bigger lathes on their feet. The press bed and bottom plate are bolted in so i can remove them with the jack. Then i can straddle my lathe bed and with a 1/2T chain hoist attached to the top of the press frame i can safely lift my heavy parts. Enjoy. ???? just ask...Bob