- Joined

- Apr 21, 2015

- Messages

- 894

And here's the 10", with a surprise announcement to follow...

Needs a new belt. This one slips terribly. I've already found the specs from Logan Actuator.

My father disassembled the lathe years ago to restore it, including painting it, but never finished. First a move and then later a divorce threw off those plans.

Fortunately he has what we think are all of the parts.

The shiny chuck is a Shars special I picked up about 6 months ago. The old chuck was in rough shape, and we could never get it tightened enough to take any but the slightest cuts.

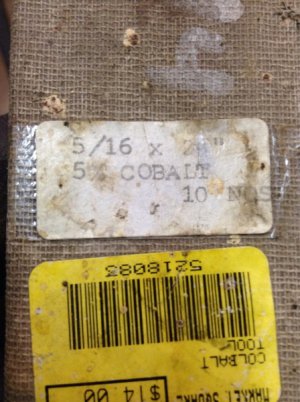

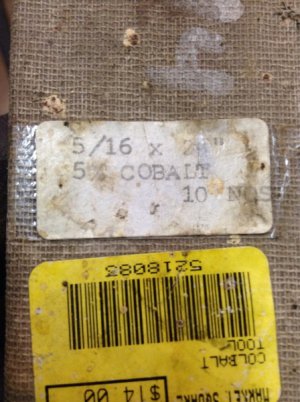

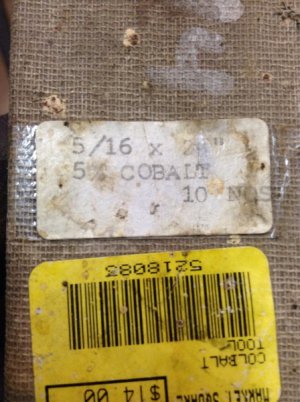

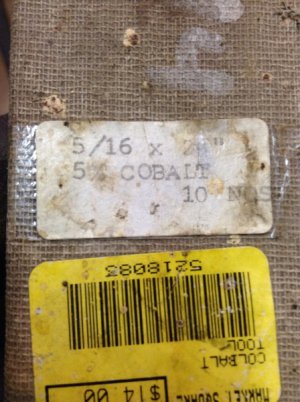

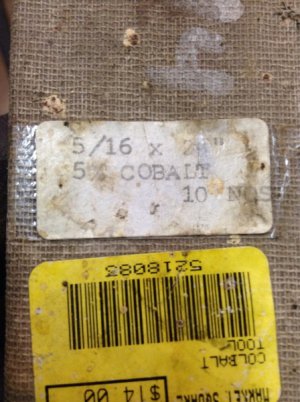

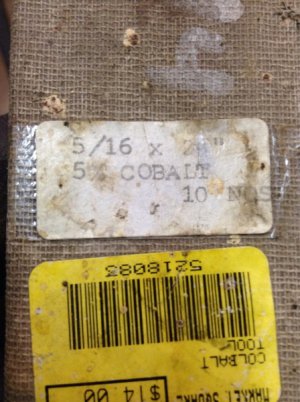

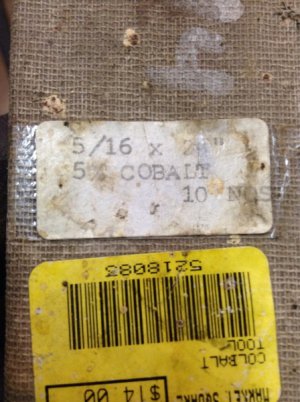

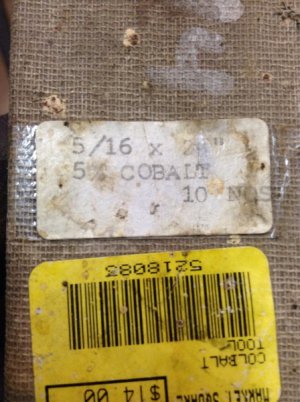

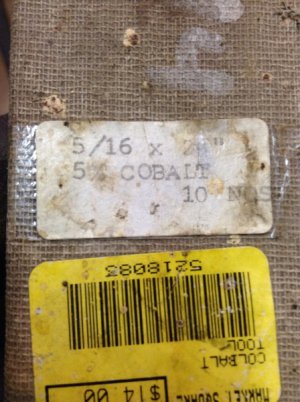

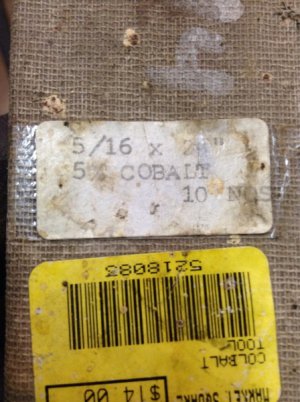

Of the tooling he has this excites me the most. It's a 10-pack of cobalt tool steel blanks that I can grind as I see fit. (Again, I have a T&C/universal grinder, but no tooling or fixtures for anything but surface grinding, and no real knowledge of how to use it yet anyway.)

Needs a new belt. This one slips terribly. I've already found the specs from Logan Actuator.

My father disassembled the lathe years ago to restore it, including painting it, but never finished. First a move and then later a divorce threw off those plans.

Fortunately he has what we think are all of the parts.

The shiny chuck is a Shars special I picked up about 6 months ago. The old chuck was in rough shape, and we could never get it tightened enough to take any but the slightest cuts.

Of the tooling he has this excites me the most. It's a 10-pack of cobalt tool steel blanks that I can grind as I see fit. (Again, I have a T&C/universal grinder, but no tooling or fixtures for anything but surface grinding, and no real knowledge of how to use it yet anyway.)