- Joined

- Apr 21, 2015

- Messages

- 894

My brother has both of my father's old lathes in his garage. It's a shame because he doesn't seem to be inclined to use them, but then I don't have room for either. I'm trying to get them tooled out for use (as I'm free to use them any time), but I need help making a couple selections.

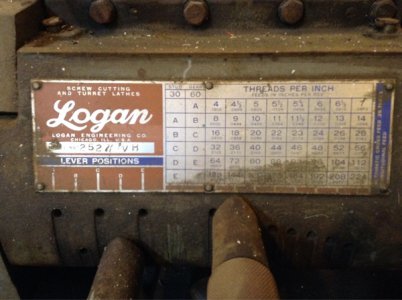

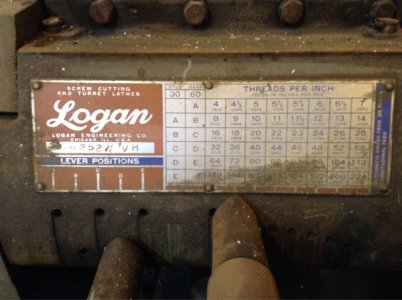

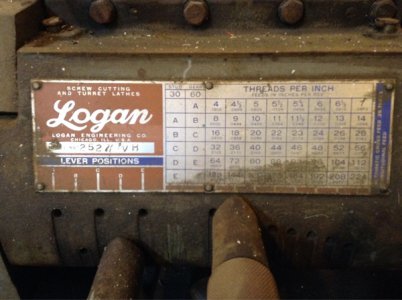

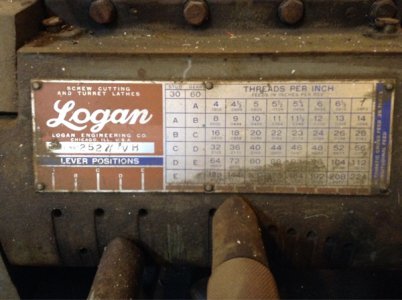

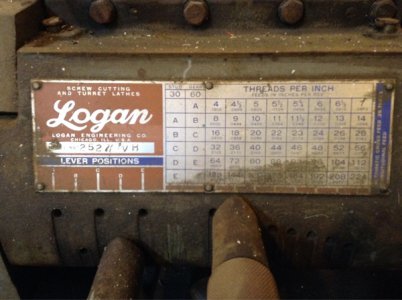

Both have lantern-style tool holders, so those are all I've ever used. I hate them. I want to get QCTPs for both. But the question is, can I use the same size for both? One is a 10" model 850, the other a 12" model 2525V.

The writeups I see say that the AXA size covers a range including both. But is that advisable? Since the BXA would fit the 12", would I be better off there? I imagine the thicker tool holders will experience less chatter, all else being equal. But is it enough to matter? Obviously there is a real benefit to being able to use the same tools on either machine.

Also I need a starter set of tooling. I expect to be cutting a lot of aluminum (I melt my own aluminum for practice stock), a fair amount of mild steel, and occasionally some stainless or tool steel for small rods, pins, etc. I am going to be placing an order with Shars this weekend for some other things (vise for the grinder, better indicator holder, and more), so that would be the ideal place for me to shop. My dad still has a couple boxes of different sizes of parting tools (industrial surplus of some sort) that I should be able to use, so turning, facing, and boring tools appropriate for my tasks are needed. I've only had maybe 10 hours on the lathe so far, so let's just pretend I don't know anything, so please spell it out for me. Thanks!

Both have lantern-style tool holders, so those are all I've ever used. I hate them. I want to get QCTPs for both. But the question is, can I use the same size for both? One is a 10" model 850, the other a 12" model 2525V.

The writeups I see say that the AXA size covers a range including both. But is that advisable? Since the BXA would fit the 12", would I be better off there? I imagine the thicker tool holders will experience less chatter, all else being equal. But is it enough to matter? Obviously there is a real benefit to being able to use the same tools on either machine.

Also I need a starter set of tooling. I expect to be cutting a lot of aluminum (I melt my own aluminum for practice stock), a fair amount of mild steel, and occasionally some stainless or tool steel for small rods, pins, etc. I am going to be placing an order with Shars this weekend for some other things (vise for the grinder, better indicator holder, and more), so that would be the ideal place for me to shop. My dad still has a couple boxes of different sizes of parting tools (industrial surplus of some sort) that I should be able to use, so turning, facing, and boring tools appropriate for my tasks are needed. I've only had maybe 10 hours on the lathe so far, so let's just pretend I don't know anything, so please spell it out for me. Thanks!