- Joined

- Aug 7, 2013

- Messages

- 655

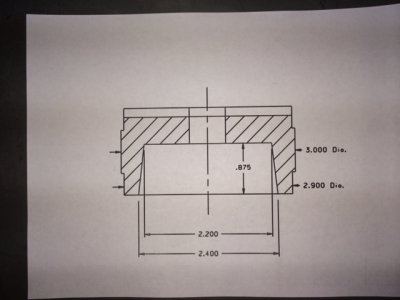

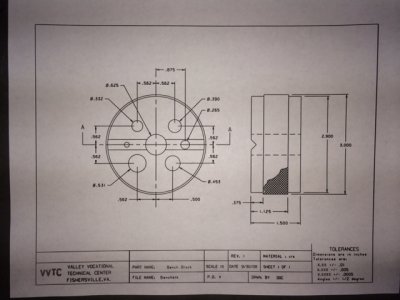

If I can get the plans put in as attachments I'll be glad to email them to you. Otherwise I'll have to snail mail the. That's not a problem just slower. My cad system is about 30 yrs. old. Let me see what I can come up with.

Gary

What CAD are you using?

Sounds like you're doing a nice job teaching those kids! Keep it up!