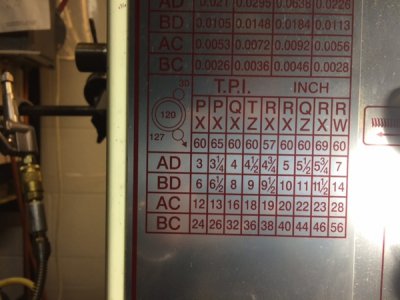

A few notes on the above information. Seems to be a number of variations, and probably versions of the manual. The Acer site does have a download copy for the 1340G. The threading/feeding tables are a bit different then the picture above, so worth doing some scribe cuts on stock to verify the TPI. Manual download for the Dynamic model:

http://www.aceronline.net/acergroup/manuals/manual-el-dyn1340g_1440e.pdf or for the VFD E-lathe model

http://www.aceronline.net/acergroup/manuals/manual-el-el1440v.pdf . It is interesting that the thread chart for the E-Lathe (VFD) is even different then the name plate and what you have indicated. The other note is looking at the schematic for both machines and how they address the wiring when converted to VFD operation and the connections for the coolant, fan, etc. The VFD model is a real beauty and well implemented.

On the Dynamic 1340G, you can use the power light hole for the VFD pot, you will either need to make a bushing 3/8" hole to 22mm for a standard pot to fit or you can buy a 22 mm speed pot. You still need an indicator light to show that the machine is powered. I would suggested getting a lighted Jog or E stop switch and connecting the current power light 24VAC to the indicator lamp. The switches usually are standard 22mm (the E-Stop could be 30mm), so something like this switch for the Jog button could be used for both Jog and a power ON light.

https://www.automationdirect.com/ad...ushbuttons_Flush_-a-_Extended/LED/GCX1202-24L

https://www.automationdirect.com/ad...dicators/22mm_Metal/Potentiometers/ECX2300-5K

https://www.automationdirect.com/ad..._Indicators/22mm_Metal/Potentiometers/ECX2640

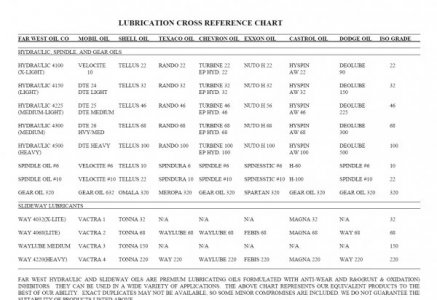

The oils mentioned are a bit antiquated terminology, but for the most part there are modern day ISO weight equivalents. Note that there are various nomenclature for oil viscosity and they have different properties at different temperatures, ISO, AGMA, SAE motor Oil, SAE Gear Oil, API... they use different nomenclatures and have numbers/weights are not interchangeable. It is controversial about which oils can be used in machines (lathe, mill), any oil is better than none, but try to use the appropriate oil for your type of machine to ensure its longevity. When you consider that you change the oil maybe once a year, it pays not to scrimp a few dollars to get an automotive oils instead of a proper machine oils. I have attached an updated chart which gives the recommend oils for the Acer lathes and your model.

Headstock and gearbox uses Tellus 27, the modern day would be an ISO32 or ISO 46 hydraulic or circulating gear oil, non detergent. (examples: Mobile DTE 24 or 25, Mobil DTE Light or DTE Medium). All readily available at local farm supply stores, or online.

Apron Tonna 33, is a bit of a strange duck. Normally the Tonna was Shells version of way oil, so a bit stickier. It is not uncommon to use way oil in some aprons, but in general I usually see a standard ISO 68 hydraulic/gear oil used. The equivalent would be Mobil DTE 26 hydraulic oil or Mobil heavy medium circulating gear oil which are both ISO 68.

On the ways and horizontal sliding surfaces I would recommend Vactra #2 or any ISO 68 way oil, the addition of tacifiers and film properties of way oil allow surfaces to float on each other, yet not get gummy and have chips stick to it.

Work out what you want to do sequentially, nice to see you got the machined moved without mishap. You can never be too careful, so do not rush it.

Mark

View attachment 142767

View attachment 142770