Sorry it just sold for $110. I missed it.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Setting up my Acra 16x40 lathe - DRO, Tool post, VFD/Controls, & Tooling

- Thread starter slodat

- Start date

I just bought a Mitutoyo lathe DRO package from Mike at Can Do Machinery. Wouldn't hesitate doing it again. Mike was great to deal with, and no one else came close to his prices on Mitutoyo. Very happy with the DRO ( 2 axis, not 3 ) on my Summit 1440B. It has a magnetic scale on the Z axis, and glass on the X.

Nice score on the machines, BTW!

candomachinery.com

candomachinery.com

Nice score on the machines, BTW!

Can-Do Machinery Sales - Specializing in Digital Readouts - DRO's

- Joined

- Jan 20, 2021

- Messages

- 296

Yes, it's a Korean lathe. From what I'm seeing online folks say it's a high quality machine.You might want to check out https://www.machine-dro.co.uk/

I think the dollar is pretty strong now against the pound.

Korean lathe?

I had just ordered the MX-200L from PM when I saw your reply. Thanks for the info!I just bought a Mitutoyo lathe DRO package from Mike at Can Do Machinery. Wouldn't hesitate doing it again. Mike was great to deal with, and no one else came close to his prices on Mitutoyo. Very happy with the DRO ( 2 axis, not 3 ) on my Summit 1440B. It has a magnetic scale on the Z axis, and glass on the X.

Nice score on the machines, BTW!

Can-Do Machinery Sales - Specializing in Digital Readouts - DRO's

candomachinery.com

- Joined

- Jun 12, 2014

- Messages

- 4,826

Looks like a 1735 RPM 4 pole 14A@220V so there are very few 3.7 kW native single phase VFD's and the only one i would recommend is the Yaskawa GA500, I have done several installs with them. It is a very wide unit. Alternate is a 3 phase VFD used in derated mode, typically the WJ200-075LF is used. They need to be run on a minimum 50A circuit and I would recommend fusing or dedicated breaker for the circuit. I assume you do not have 3 phase? If 3 phase is something you may have in the future then I would lean to a 3 phase unit run in single phase mode but also can be configured for 3 phase input. I have Yaskawa VFD's on both my mill and lathe and they have 3 phase inputs but can also be run off of single phase. Shop around, there prices can vary significantly If you need model numbers or sppecifics let me know. There are recent threads on lathe builds with both these VFDS.

That is a nice DRO, I have the EL700 on my mill which is essentially the same unit with 4 axis. It is a touch screen, you will want to put a screen protector over the whole display, I used ones for a tablet and cut it down to size to fit.

That is a nice DRO, I have the EL700 on my mill which is essentially the same unit with 4 axis. It is a touch screen, you will want to put a screen protector over the whole display, I used ones for a tablet and cut it down to size to fit.

- Joined

- Jun 12, 2014

- Messages

- 4,826

Suitable VFD's are listed below, one would need to map out the current controls to determine a replacement control system, and in addition you need to consider other sub-systems like if it has a pressure lube system, clutch drive, etc. Since you will be powering two systems, and the Haas would also need 3 phase, in the long run you might be better off with a Phase Perfect 10 or 20 Hp unit or an RPC with a power distribution panel. I like VFD's on lathes, but at the end of the day you will probably spend 2K in the conversion and then you still need to power the Haas.

Hitachi Drives WJ200-075LF (single phase input rating is 18.4A)- $804

www.wolfautomation.com

www.wolfautomation.com

Hitachi Drives P1-00460-LFUF (single phase input rating is 15.5A) - $843

https://www.wolfautomation.com/vfd-10-hp-3-phase-200-240v-32-44-46-a-1/

YASKAWA GA500 INDUSTRIAL AC MICRODRIVE GA50UB018ABA native 1/PH 240V 5.0 HP 17.6 AMPS ND -$675

Note: some of the vendors offer a discount if you sign up for email

Phase Perfect:

www.phasetechnologies.com

www.phasetechnologies.com

Related threads:

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

Hitachi Drives WJ200-075LF (single phase input rating is 18.4A)- $804

WJ200-075LF

WJ200-075LF quick delivery, authorized Hitachi Drives distributor. Offers complete line of AC Drives . Easy online ordering, rewards program, and great pricing.

Hitachi Drives P1-00460-LFUF (single phase input rating is 15.5A) - $843

https://www.wolfautomation.com/vfd-10-hp-3-phase-200-240v-32-44-46-a-1/

YASKAWA GA500 INDUSTRIAL AC MICRODRIVE GA50UB018ABA native 1/PH 240V 5.0 HP 17.6 AMPS ND -$675

YASKAWA GA500 INDUSTRIAL AC MICRODRIVE MODEL# GA50UB018ABA 1/PH 240V 5.0 HP 17.6 AMPS ND

STOCK IS SUBJECT TO CHANGE WITHOUT NOTICE. THIS PRODUCT HAS EXTENDED LEAD TIMES, CONTACT US FOR ESTIMATED AVAILABILITY DATE.

prbelectronics.com

Note: some of the vendors offer a discount if you sign up for email

Phase Perfect:

Phase Perfect Performance | Single to Three Phase Power Converter | Variable Frequency Drives and Digital Phase Converters | Phase Technologies

Three-phase power from a single-phase source anywhere you need it. Phase Perfect® digital phase converter uses modern solid-state electronics to create utility-quality three-phase power anywhere.

Related threads:

New ACRA 1440C lathe with Mark Jacobs VFD

Earlier this summer I received my new ACRA 1440C lathe. At 2700 pounds there was no way I was wanting to deal with the unloading duties. I ended up having it delivered to a local crane service company. When it arrived they unloaded the machine from the delivery semi and loaded it on their flat...

www.hobby-machinist.com

www.hobby-machinist.com

PM 1440TL with Hitachi WJ200-075LF VFD Delivery, Clean up and VFD Set up

My PM 1440TL arrived on Friday and I spent the weekend getting the machine in place, cleaning off all the rust preventative and finishing all the VFD wiring. Took the whole weekend and I put together a video of the process from truck delivery, using a forklift and rollers to get it in place...

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Jan 20, 2021

- Messages

- 296

Mark - thank you for the information! I have used the SJ-P1 drives in two other machines with great success. I have the 20hp SJ-P1 in my Tree J425 CNC mill and it has worked well with single phase supply.

I only have single phase service in the shop. I do have a 20hp American Rotary RPC that feeds a 3 phase distribution panel. I doubt I'll get three phase in the shop. Mostly because the PUD will only do 208Y and I don't want to have to upsize every conductor in the shop. I may go to 400a single phase at some point, time will tell.

The Haas TM1 is rated for single phase supply. Only takes a 40a feeder. So, that's how I'll handle the Haas. Currently, the only machine that runs on the RPC is a 15hp American Pacemaker lathe. The RPC runs it quite well. I only start the motor in its lowest speed and I don't have issues. It is a clutch machine so there aren't a lot of start/stops like this Acra lathe will have.

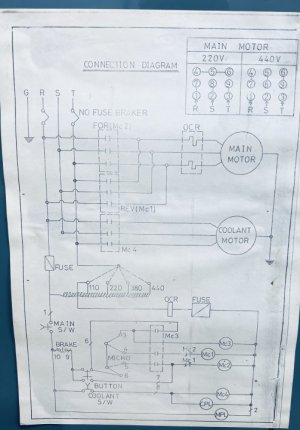

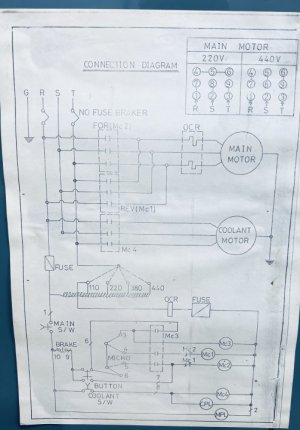

On to the Acra.. I obviously could power it up from the RPC. The lathe also came with a static phase converter. That is how the previous owner powered it up. I'm wanting to do a VFD because I really like your control setup. I am a high voltage relay technician by trade. So, I understand controls and such. I have attached the schematic that's inside the control enclosure door.

I only have single phase service in the shop. I do have a 20hp American Rotary RPC that feeds a 3 phase distribution panel. I doubt I'll get three phase in the shop. Mostly because the PUD will only do 208Y and I don't want to have to upsize every conductor in the shop. I may go to 400a single phase at some point, time will tell.

The Haas TM1 is rated for single phase supply. Only takes a 40a feeder. So, that's how I'll handle the Haas. Currently, the only machine that runs on the RPC is a 15hp American Pacemaker lathe. The RPC runs it quite well. I only start the motor in its lowest speed and I don't have issues. It is a clutch machine so there aren't a lot of start/stops like this Acra lathe will have.

On to the Acra.. I obviously could power it up from the RPC. The lathe also came with a static phase converter. That is how the previous owner powered it up. I'm wanting to do a VFD because I really like your control setup. I am a high voltage relay technician by trade. So, I understand controls and such. I have attached the schematic that's inside the control enclosure door.

- Joined

- Jun 12, 2014

- Messages

- 4,826

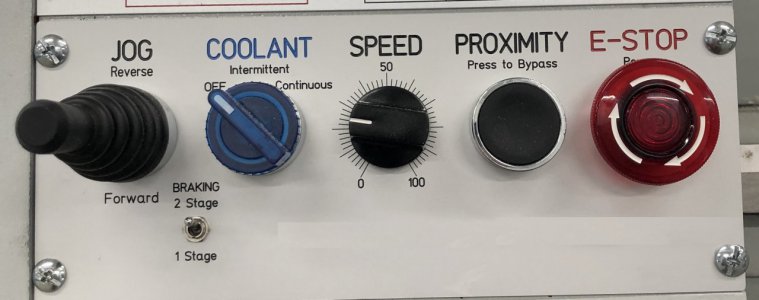

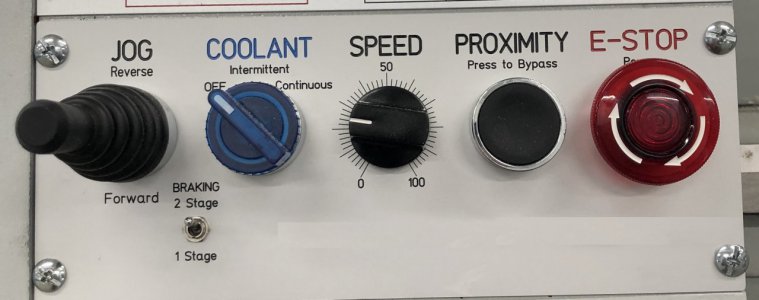

OK, got it. Not a very complicated setup and they are very nice lathes. If you went with a VFD setup, I would pretty much remove all the current electrical and switch gear and just do a complete replacement system. The systems I build, I use control relays with a separate power supply and 2-3 levels of redundancy, but pretty much designed around a proximity stop system. I have some simple single relay designs that can be powered by the VFD supply and are an easy install. You could use the current control panel, but on some machines I find it easier to just replace it and outsource that. Since I integrate the lights into the switch it saves other holes for say a speed pot and an E-Stop. I like to put the main power disconnect on the side of the control box if on the machine or on the VFD enclosure if you go that route. Given the size and depth of the VFD's I would suggest just replacing the control cabinet with a deeper one and mount it to the machine. Pretty much remove all the existing wiring and switch gear other than spindle switch. You should have enough volume in the cabinet to not need venting, unless you are doing aggressive turning for extended periods. You can give me a call or email if you want to get into some of the designs.

Mark

Mark

- Joined

- Jan 20, 2021

- Messages

- 296

Went ahead and ordered the WJ200-075LF. I had a $25 credit from the last drive I ordered from Drives Warehouse. This is the third I've bought from them. Prices are significantly better than Wolf Automation and they ship super fast. The P1 drive is out of stock for at least a couple months.

Also ordered a 24H x 16W x 12D enclosure from Factory Mation. These enclosures have some of the best pricing I've been able to find.

Also ordered a 24H x 16W x 12D enclosure from Factory Mation. These enclosures have some of the best pricing I've been able to find.

Last edited: