- Joined

- Jun 10, 2013

- Messages

- 115

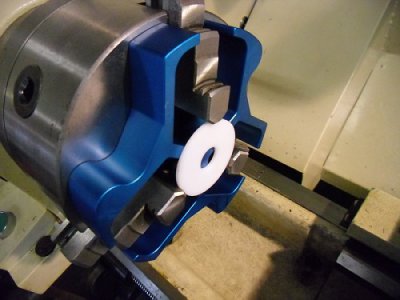

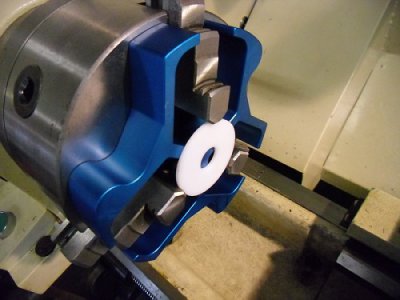

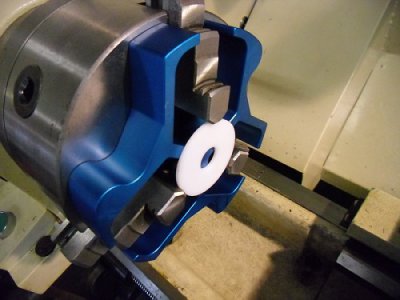

Royal Chuck Stop - review: I've looked at these for a while but could not justify the price but I talked my employer to spring for the $ as I do occasional small jobs at home because "we are in a hurry".

http://www.royalprod.com/product.cfm?catID=12

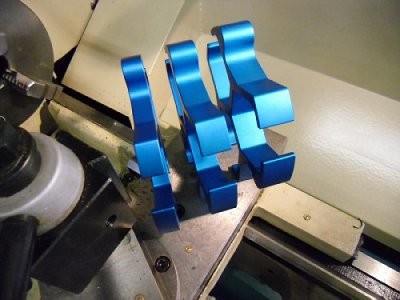

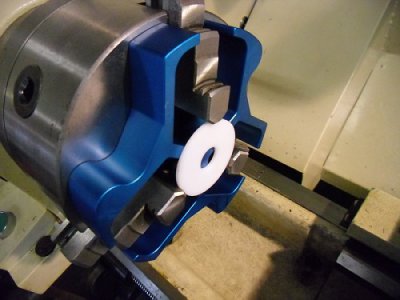

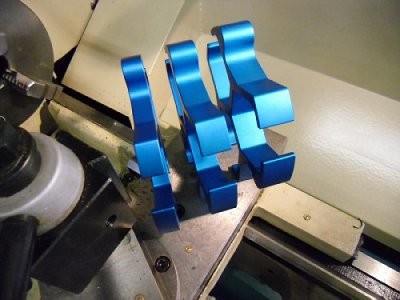

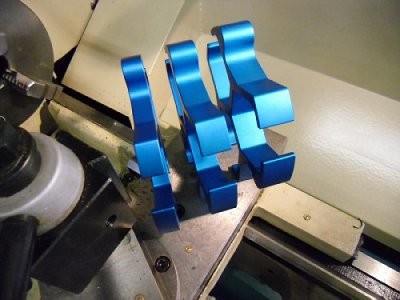

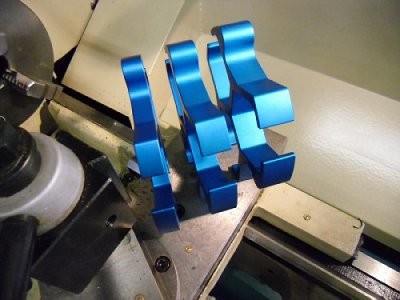

Nicely made, simple in design and operation, a good way to square thin parts. Yep, those are magnets and they do just fine, this is shown on a 6" chuck. Spendy - about $100 each, I got the 3 pc set as they are different thicknesses for depending on your application. Of course the blue anodize is a nice finishing touch.

Two thumbs up :thumbsup2::thumbsup2:

http://www.royalprod.com/product.cfm?catID=12

Nicely made, simple in design and operation, a good way to square thin parts. Yep, those are magnets and they do just fine, this is shown on a 6" chuck. Spendy - about $100 each, I got the 3 pc set as they are different thicknesses for depending on your application. Of course the blue anodize is a nice finishing touch.

Two thumbs up :thumbsup2::thumbsup2: