-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

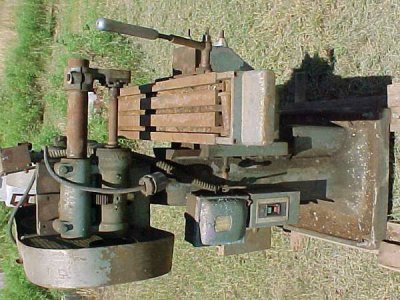

Restoring A Burke #1 Horizontal

- Thread starter USNFC

- Start date

- Joined

- Jan 12, 2013

- Messages

- 133

Thanks, yeah at first I was just going to clean up the ways, lube, and then use it...but I figured I may as well go all out while I have it disassembled. There aren't any machines in my shop that can walk the runway, but this one should look pretty good when I'm done. I'm more concerned with function over beauty, but maybe I can get both!

- Joined

- Jan 2, 2014

- Messages

- 8,852

Thanks for the pictures!

Very nice job!!!

That looks very similar to an old Bristol mill that's patiently waiting for my attention.....

Please a little more info:

-any idea the age of the machine?

-does it have adjustable gibs for the dovetails?

-what is the spindle taper MT3?

-what (chemicals, tools, process) did you use to clean the table?

-what for the ways?

-what paint did you use?

-did you need to fill any casting lumps or holes? If so with what?

Thanks again!

-brino

(my Bristol is from early 1900's, it has a MT3 spindle taper, I got it from a local scrap yard)

Very nice job!!!

That looks very similar to an old Bristol mill that's patiently waiting for my attention.....

Please a little more info:

-any idea the age of the machine?

-does it have adjustable gibs for the dovetails?

-what is the spindle taper MT3?

-what (chemicals, tools, process) did you use to clean the table?

-what for the ways?

-what paint did you use?

-did you need to fill any casting lumps or holes? If so with what?

Thanks again!

-brino

(my Bristol is from early 1900's, it has a MT3 spindle taper, I got it from a local scrap yard)

- Joined

- Jan 12, 2013

- Messages

- 133

Thanks Brino.

To answer your questions:

-I'm not sure of the age, but I believe it is shortly after Burke acquired USMT. I would guess 1950's, but that is just a guess.

-The gibs are adjustable with sets screws and bolts to push and pull.

-The spindle taper is B&S 9

-To clean the table I used WD40, PB Blaster, a scotchbrite(by hand, not powered)

-For the ways, it took a lot of elbow grease, PB blaster, and steel wool.

-The paint I used was Rust-X machine grey.

-I didn't bother filling any casting flaws, or removing really stubborn original paint...I figured if it was that much of a pain, then it wasn't going anywhere under normal use.

Now, to add, I have used bondo before to fill casting flaws and it works well. I'm no painter, but what I have learned is preparation is the biggest key. I didn't do a professional quality job, but I did do a better than average job. Like I said, at first I was just going to remove the rust, clear over it, clean up performance issues, then use it....but I got carried away and decided to go ahead and make it pretty. My biggest focus is always making sure to do the mechanical and electrical aspects as perfectly as possible. I know some people wouldn't put a scotchbrite pad to the table, but I've never had an issue with it. I did steer clear of using it on the ways because I've read reports of impregnating the stuff into the metal, which will cause wear...not sure of the validity, but better safe than sorry. I will update with pic's as I progress. Thanks again for the comments.

To answer your questions:

-I'm not sure of the age, but I believe it is shortly after Burke acquired USMT. I would guess 1950's, but that is just a guess.

-The gibs are adjustable with sets screws and bolts to push and pull.

-The spindle taper is B&S 9

-To clean the table I used WD40, PB Blaster, a scotchbrite(by hand, not powered)

-For the ways, it took a lot of elbow grease, PB blaster, and steel wool.

-The paint I used was Rust-X machine grey.

-I didn't bother filling any casting flaws, or removing really stubborn original paint...I figured if it was that much of a pain, then it wasn't going anywhere under normal use.

Now, to add, I have used bondo before to fill casting flaws and it works well. I'm no painter, but what I have learned is preparation is the biggest key. I didn't do a professional quality job, but I did do a better than average job. Like I said, at first I was just going to remove the rust, clear over it, clean up performance issues, then use it....but I got carried away and decided to go ahead and make it pretty. My biggest focus is always making sure to do the mechanical and electrical aspects as perfectly as possible. I know some people wouldn't put a scotchbrite pad to the table, but I've never had an issue with it. I did steer clear of using it on the ways because I've read reports of impregnating the stuff into the metal, which will cause wear...not sure of the validity, but better safe than sorry. I will update with pic's as I progress. Thanks again for the comments.