-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Request For An HSS Lathe Cutter Primer for Boring Bars

- Thread starter WCraig

- Start date

- Joined

- Apr 28, 2014

- Messages

- 3,590

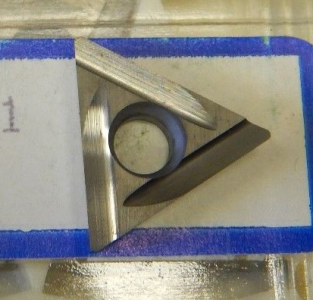

Komet Inserts, the style with the ground chip breaker, have always worked well for me. Very low tool pressure.I guess I never bought it to the idea that you can't use carbide on small lathe's. That is what I use 99% of the time. Inserts have come along ways over the years.

I discovered them in the '80s when I was designing a multi-stage boring bar for aluminum road wheels. Created excellent chips instead of strings.

- Joined

- Jan 31, 2016

- Messages

- 11,471

So, is this a boring tool?

Yes , it's a boring bar . It is used in a boring head and will work on the lathe as well .

- Joined

- Nov 15, 2016

- Messages

- 943

The thing in the photo look like a flycutter, the giveaway being the shank.

You may find this useful:

You may find this useful:

- Joined

- Dec 30, 2018

- Messages

- 73

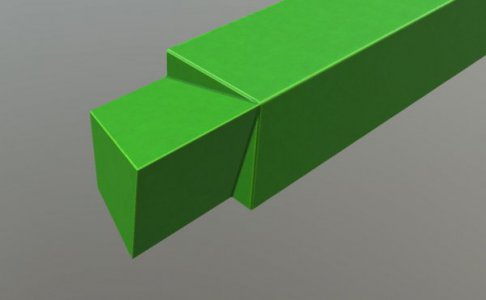

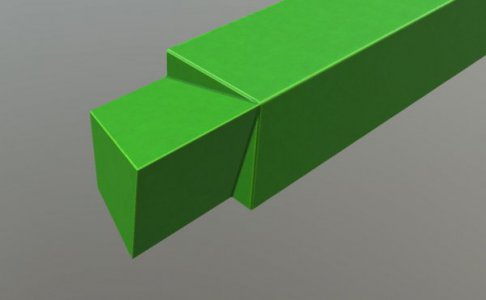

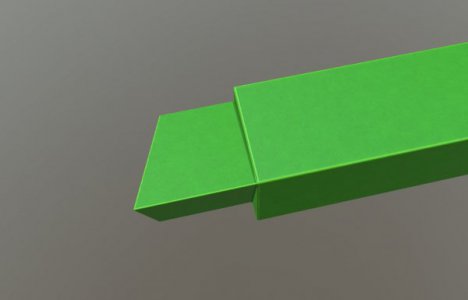

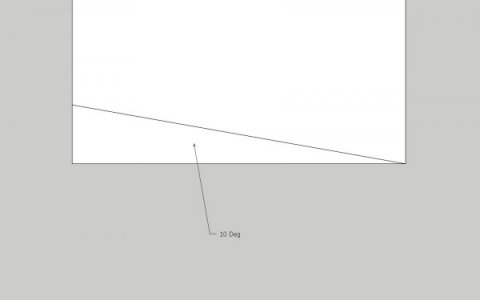

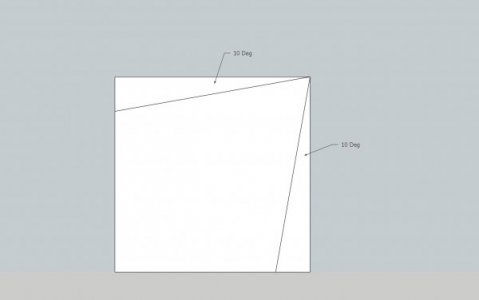

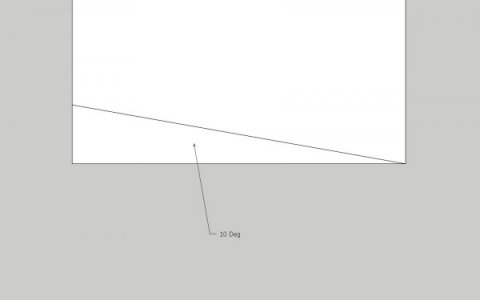

Here a quick 3d model I did of one of the bits that I use a lot on my mini lathe:

Perspective

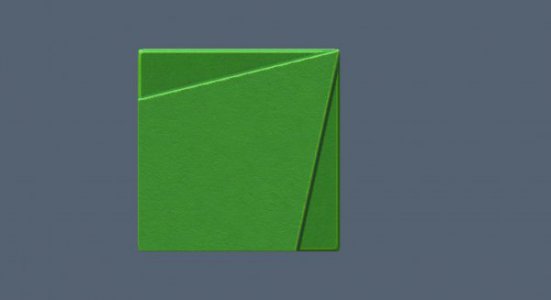

Front Ortho View

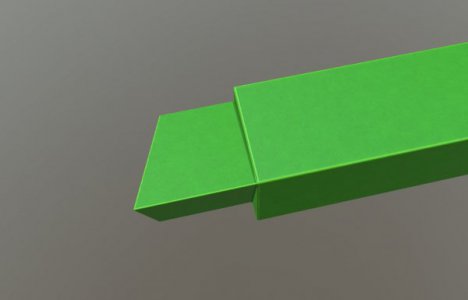

Top Perspective.

The rake and relief angles are a bit exaggerated but you get the idea.

For me it works for plastics, brass, aluminium and steel. On plastics you can remove a lot of material in one pass since the leading edge does a lot of the cutting work.

For steel it might be an idea to reduce the angles a bit in order to make the tip more robust.

Rounding the tip slightly with a sharpening stone ensures a good finish as well.

When I got my mini lathe I used carbide, but I prefer the versatility and sharpness of self ground HSS.

Perspective

Front Ortho View

Top Perspective.

The rake and relief angles are a bit exaggerated but you get the idea.

For me it works for plastics, brass, aluminium and steel. On plastics you can remove a lot of material in one pass since the leading edge does a lot of the cutting work.

For steel it might be an idea to reduce the angles a bit in order to make the tip more robust.

Rounding the tip slightly with a sharpening stone ensures a good finish as well.

When I got my mini lathe I used carbide, but I prefer the versatility and sharpness of self ground HSS.

- Joined

- Dec 30, 2018

- Messages

- 73

Found a photo:

The tip looks blunt, but that is just some aluminium that I cut.

I have accidentally brushed my hand against it a couple of times - the thing cuts like a knife.

On the right you can see my 2mm parting bit.

I had absolutely no luck with the carbide parting bit that I got when I bought the lathe.

The tip looks blunt, but that is just some aluminium that I cut.

I have accidentally brushed my hand against it a couple of times - the thing cuts like a knife.

On the right you can see my 2mm parting bit.

I had absolutely no luck with the carbide parting bit that I got when I bought the lathe.

- Joined

- Dec 30, 2018

- Messages

- 73

Hi Mikey,

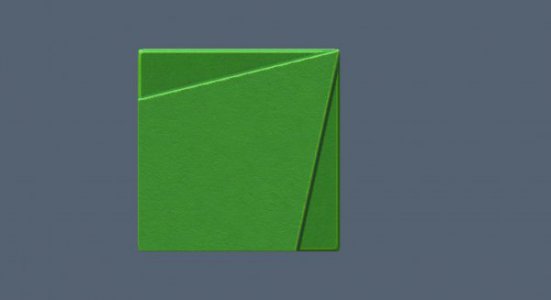

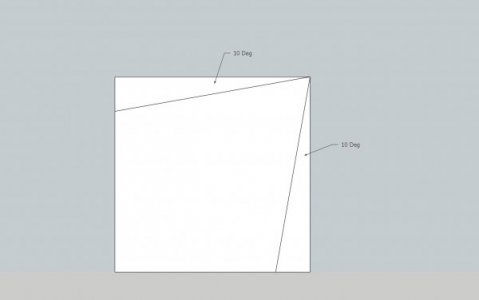

When I ground the bit I did not really pay attention to the angles, but this looks about right: 10 degrees all round.

I don't have a back rake on the bit, but since I use it as a "Side Cutter" I guess the 10 degrees at the top actually serves as a back rake.

With this bit I normally advance the cross slide to the desired position and then cut in from right to left.

I have a bit that I ground a while back that has back rake, but I rarely use it. Sharpening a bit with back rake lowers the cutting edge which means fiddling around with shims and stuff.

On this one the main cutting edge can be 'restored' by just grinding off less than half a mm from the front.

When I ground the bit I did not really pay attention to the angles, but this looks about right: 10 degrees all round.

I don't have a back rake on the bit, but since I use it as a "Side Cutter" I guess the 10 degrees at the top actually serves as a back rake.

With this bit I normally advance the cross slide to the desired position and then cut in from right to left.

I have a bit that I ground a while back that has back rake, but I rarely use it. Sharpening a bit with back rake lowers the cutting edge which means fiddling around with shims and stuff.

On this one the main cutting edge can be 'restored' by just grinding off less than half a mm from the front.

Last edited:

- Joined

- Dec 20, 2012

- Messages

- 9,422

Thanks, Duke! Helps to know the angles so the guys can reproduce it if they choose.

Lots of guys don't use back rake. Seems they feel it makes it easier to regrind the bit at need without having to refresh all the angles. I have a different opinion on back rake but that isn't relevant here. I was just curious as to why you left it out. The angle on top of your tool is side rake only, by the way.

Lots of guys don't use back rake. Seems they feel it makes it easier to regrind the bit at need without having to refresh all the angles. I have a different opinion on back rake but that isn't relevant here. I was just curious as to why you left it out. The angle on top of your tool is side rake only, by the way.