- Joined

- Jul 15, 2020

- Messages

- 421

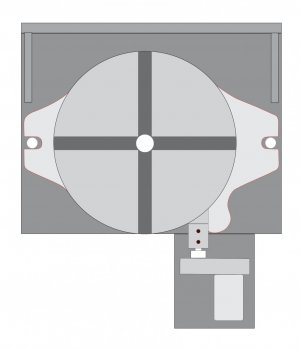

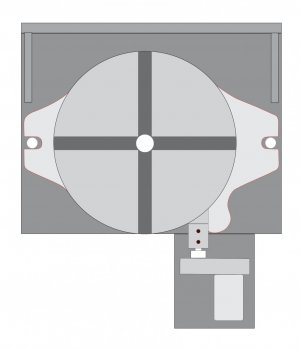

Since I purchased a slightly larger Yuasa rotary table, i have no need for my old 9" Troyke BH-9. Since they are not worth a great deal on the used market, I thought I might try my hand at using it as a welding positioner.

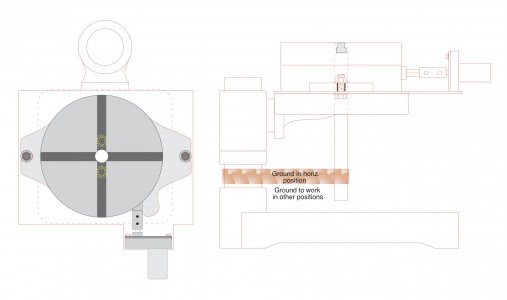

Using it solely as a flat, horizontal positioner requires virtually no fabrication or modification. I coupled it with an adaptor to a Grainger gear motor, and hooked it up to an electric train transformer. It rotates easily and has a broad speed range in forward and reverse.

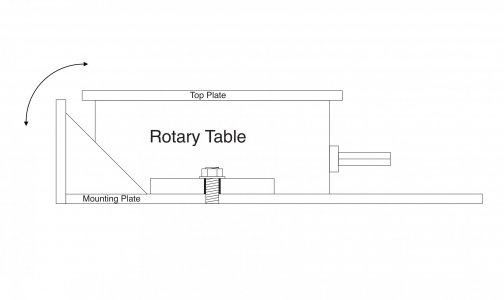

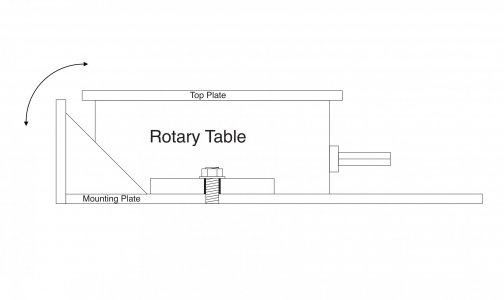

I plan to fabricate a right angle mounting plate for it so it can be used both horizontally and vertically. The motor rests perfectly flat against the mounting plate, and is held in place by the coupler. There is little to no oil in the unit, so leakage shouldn't be a problem if used vertically. I'll need to make a top plate for it to protect the top of the unit and provide some clamping holes, etc.

I happened to have several of the gear motors and a transformer on hand, so the project cost me nothing. Kind of a dumb project, but fun to experiment with.

Using it solely as a flat, horizontal positioner requires virtually no fabrication or modification. I coupled it with an adaptor to a Grainger gear motor, and hooked it up to an electric train transformer. It rotates easily and has a broad speed range in forward and reverse.

I plan to fabricate a right angle mounting plate for it so it can be used both horizontally and vertically. The motor rests perfectly flat against the mounting plate, and is held in place by the coupler. There is little to no oil in the unit, so leakage shouldn't be a problem if used vertically. I'll need to make a top plate for it to protect the top of the unit and provide some clamping holes, etc.

I happened to have several of the gear motors and a transformer on hand, so the project cost me nothing. Kind of a dumb project, but fun to experiment with.