-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuilding a Van Norman #12 in UK

- Thread starter Pauldarby1

- Start date

- Joined

- Aug 26, 2013

- Messages

- 35

- Joined

- Nov 24, 2013

- Messages

- 1,791

Awesome build man. I almost got a #12 if only they has a quill.

hmmm that's interesting. maybe they shipped without electrical parts to save on weight and since things might be different on that side of the pond. then installed them once it was uncrated. I would love to know the history of that expat.

- Joined

- Aug 26, 2013

- Messages

- 35

My machinist has phoned to say that the table is bent!!!! It rocks on the saddle and he can't take a straight measurement. It seems that I have big problems. He was originally going to grind and then 'Turcite' it back to original size. However, he can't determine which end to use to straighten the table. Ultimately, there's no problem straightening the table, but the problem lies with re-aligning the table feed screw in the saddle. He thinks it could need grinding as much as .043" in places.

He has suggested that I may need to have the table feed screw casting ground off and machine a new one. Also there may be an option of boring out the centre of the table feed screw casting. I would then need to make an insert to the original internal diameter, but off set in the bore by the amount taken off the table to realign it.

I'm off to see him today to get a better understanding of the problem.

He has suggested that I may need to have the table feed screw casting ground off and machine a new one. Also there may be an option of boring out the centre of the table feed screw casting. I would then need to make an insert to the original internal diameter, but off set in the bore by the amount taken off the table to realign it.

I'm off to see him today to get a better understanding of the problem.

- Joined

- Feb 16, 2014

- Messages

- 146

the table is BENT? wth. I need to see this in person.

- Joined

- Aug 26, 2013

- Messages

- 35

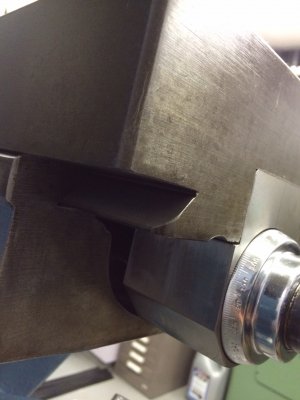

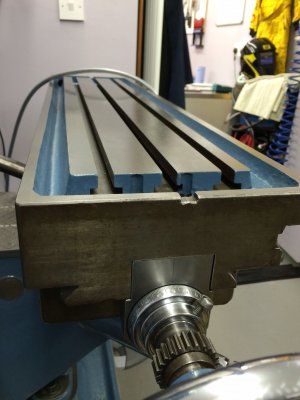

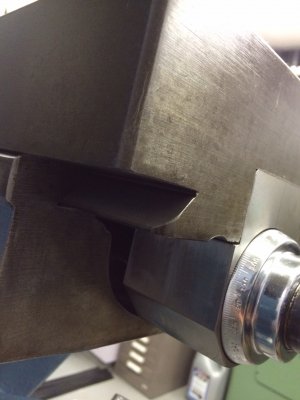

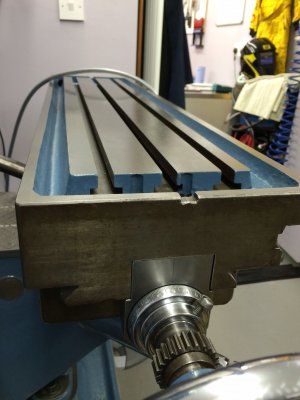

It's been a long time since the last post. I've been busy reconditioning a Jones & Shipman 1212E cylindrical grinder. I'm a sucker for a piece of machinery. I'm in the early stages of building an 1926 Indian Scout, so the machines with come in very handy. Due to the bend in the table it was decided to mill off the leadscrew casting. A new bearing housing was machined and trial fitted. A few thou at a time was taken off the depth until it could tightened up and the lead screw could be wound in and out fully without any stiffness. I think the early VN12 tables had a separate bearing housing.

Your machine is coming along nicely. I look forward to seeing it when it's done.

I'm currently working on a Van Norman No2. I'm trying to dismantle the spindle head. While it's a bit different from your spindle head, I was wondering if you have any pointers on how you rebuilt yours. Or perhaps you might have some pictures.

I'm currently working on a Van Norman No2. I'm trying to dismantle the spindle head. While it's a bit different from your spindle head, I was wondering if you have any pointers on how you rebuilt yours. Or perhaps you might have some pictures.