- Joined

- Aug 26, 2013

- Messages

- 35

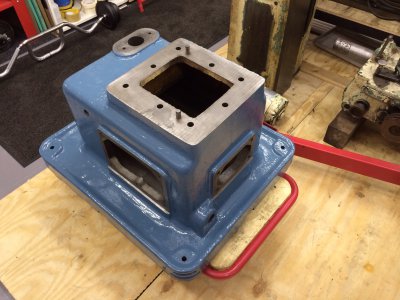

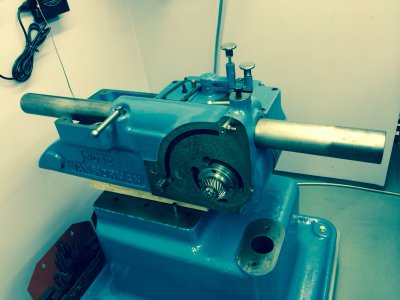

I've wanted of a while a larger milling machine to replace my Tom Senior. The Tom Senior is both a vertical and horizontal machine, but much smaller and not so easy to change over. The VN had been standing in a shed for 5 years following a bereavement. I hadn't even heard of these machines, but following some research I have been able to establish that it was built in 1947. It appears to be all there, with the exception of the right side table handwheel feed screw casting and the base side casting plate. The guy had replaced all 3 motors with 230V single phase. Fortunately he had kept the original motors. I have a 415V supply in my home workshop and intend to use the original motors. All the original electrics are there. Below the main electric box is a metal electric box containing a transformer. The output wires from this run in a metal conduit together with the main 3 phase wires to the other side of the base. Hear is located the master switch and a round 3 pin socket, fitted with a threaded screw cap. I assume this was for powering an inspection lamp.

I have almost completed the move to its new home. I only have the column and base to separate. The machine is then going to have all it's slideways and gibs reground and scraped. It's a coincidence, but both this machine and the 1926 Indian motorcycle I am building we're built in the same town/city.

I have almost completed the move to its new home. I only have the column and base to separate. The machine is then going to have all it's slideways and gibs reground and scraped. It's a coincidence, but both this machine and the 1926 Indian motorcycle I am building we're built in the same town/city.