- Joined

- May 7, 2014

- Messages

- 776

Ouuuyee. Love the caves and dim light of the fire. Lol. Had a good chuckle on that. Nice one! CG.

Merry christmas friend.

Cg.

Merry christmas friend.

Cg.

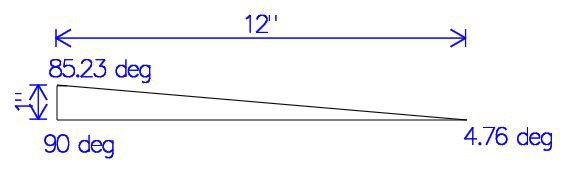

If you are stuck without a calculator Ratios can also be converted using pencil and paper. 1/12 just means a rise of 1 (unit of measurement) along a line of 12 (units of measurement) So draw a straight line 12" long, at one end measure up 1", then draw a line from there back to the start point of the first 12" line. Now you have a long narrow triangle that you can measure with a protractor. Works the same in feet, yards, miles, heck even in metric, if you americans ever drag yourself out of the middle ages

Cheers Phil