- Joined

- Feb 25, 2017

- Messages

- 59

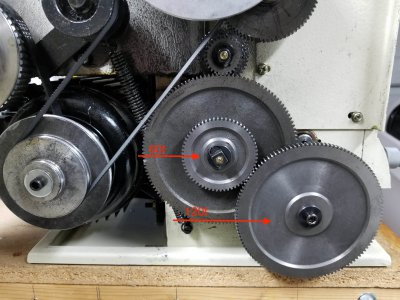

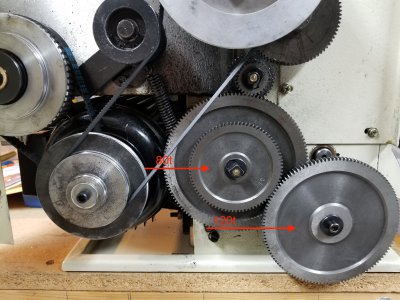

The overall ratio through the 28T-127T/120T-80T drive is .33.

The overall ratio through the 28T-127T/60T-120T drive is .11.

So the change of ratio from one configuration to the other will cut the feed rate TO one third of whatever you start with (.11/.33)

Basically I agree with RJ's approach but there might be a math correction to consider.

(RJ please note that 80/120 = .6667 and not .75)

Im going to use a dial indicator to confirm feed rate with stock gears,

Then Ill check with the 120 and the 60 swapped,

Then Ill check with the 60 in the 120 spot and the new 80 in the "B" position.

Ill post my results,

Waiting on the delivery of the 80T.

Like I said, this lathe is at .00476,

If I can reduce the feed by approx two thirds that'll be great.

I wonder why this feed rate is so fast by design ??

They gotta know as lathe designers and builders a slower feed rate is more desirable ??

Last edited: