- Joined

- Feb 25, 2017

- Messages

- 59

Hey guys,

So, my feed rate is too fast, its .0047 and if I want a really nice finish I have been hand feeding.

I got to thinking,

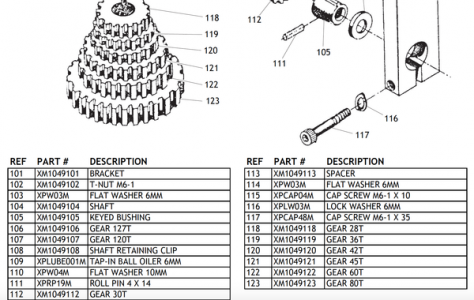

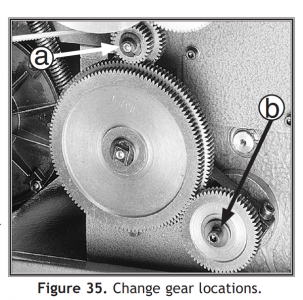

Gear "B" drives the gear box that drives the lead screw.

Gear "B" is a 60 tooth gear,

My question,

If I increased the size of gear "B" wouldn't that slow down the lead screw in turn slow down the feed rate ??

So, my feed rate is too fast, its .0047 and if I want a really nice finish I have been hand feeding.

I got to thinking,

Gear "B" drives the gear box that drives the lead screw.

Gear "B" is a 60 tooth gear,

My question,

If I increased the size of gear "B" wouldn't that slow down the lead screw in turn slow down the feed rate ??

Last edited: