- Joined

- Feb 12, 2021

- Messages

- 10

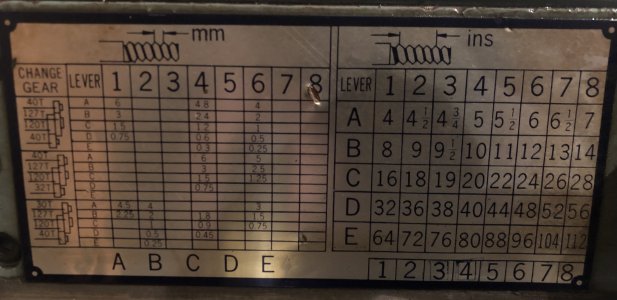

New here. Be gentle this is my first post. I recently acquired my first lathe, a Shen Wai sw-900b. From what I’m reading it’s basically the same as the g1003(and numerous others). It came with all the original equipment except the 30t and 32t metric threading gears. I know grizzly hasn’t supported these machines in forever. Does anyone here know of a source for replacements, or specs on the gears for making replacements? Sorry if this has been asked/answered before. I swear I looked.