- Joined

- Dec 3, 2013

- Messages

- 1,844

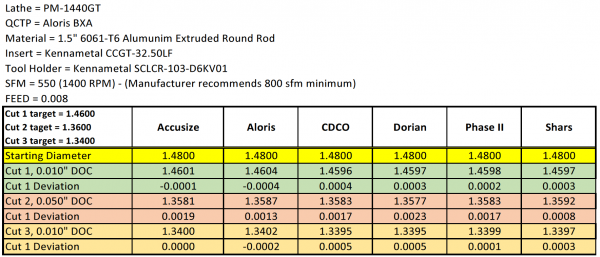

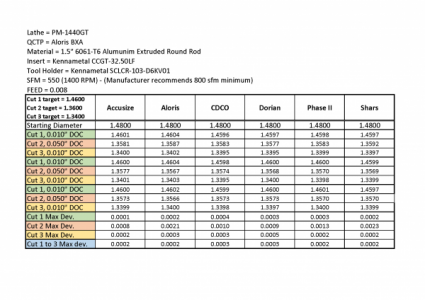

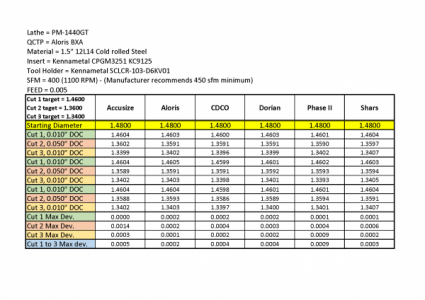

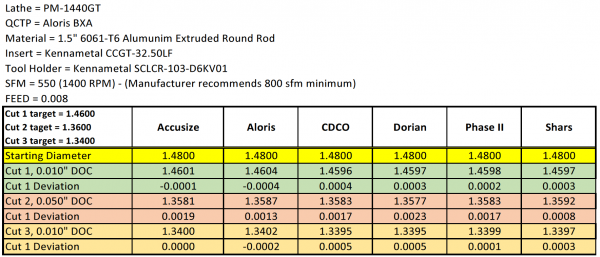

I'm still waiting on the steel but I was able to do the aluminum test cuts.

The process was use the same insert and insert tool in each of the tool holders. The stick-out of the tool was set to the same dimension for each holder.

The material was set to the same 2" stick-out from the jaws of the 8" 3-jaw chuck for each holder.

For each holder/tool the material was sized to the same 1.4800" dimension.

The first cut was a 0.010" depth of cut representing a finish pass.

The second cut was a 0.050" depth of cut representing a roughing pass.

The third and final cut was another finish pass at 0.010" depth of cut.

Each cut was 0.400" long to provide full contact of the anvils on the micrometer.

The process was use the same insert and insert tool in each of the tool holders. The stick-out of the tool was set to the same dimension for each holder.

The material was set to the same 2" stick-out from the jaws of the 8" 3-jaw chuck for each holder.

For each holder/tool the material was sized to the same 1.4800" dimension.

The first cut was a 0.010" depth of cut representing a finish pass.

The second cut was a 0.050" depth of cut representing a roughing pass.

The third and final cut was another finish pass at 0.010" depth of cut.

Each cut was 0.400" long to provide full contact of the anvils on the micrometer.