I've seen it before.Don't forget gun making in the Philippine.I hate VICE but this is a good one....

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power tool vs machine tool

- Thread starter Koi

- Start date

With all due respect how do i put a square slot in a center of a metal block.You can't possibly file it do you.A skilled person and a hand file, can make better parts then many un skilled workers with a machine tool. I do not use the die grinder near as much as I did 30 years ago, but still consider it just another tool in my arsenal. I still do lots of work with a handfile, while sitting on the deck with the wife, watching the world go by. No timelines in my world.

This shows how little and simple machines can be used to make things. Also shows why gun confiscation will not get every gun off the streets. Back in High school metal shop, I made a simple 22LR pen gun, with a pull and let go firing system. Now days, a kid would be in big trouble for even thinking about it.

- Joined

- Dec 5, 2017

- Messages

- 464

With all due respect how do i put a square slot in a center of a metal block.You can't possibly file it do you.

Drill an undersized round hole and then file it square.

Makes my arthritis flare up just thinking about it...

- Joined

- Feb 9, 2017

- Messages

- 5,250

Many times when doing fab work out in the field I've had to make slots for adjustment in steel plate. Usually I'd drill the ends of the slot and as many hole in between as I could manage. Then use my trusty die grinder connect the holes to make a slot. I have some Exacto jeweler files or a square file if I have to square the ends. Very time consuming and rarely ever came out like a mill but it got the job done. Later on when we had plasma torch with us I made several jigs I could clamp in place and cut a pretty nice square slot then clean it up with a file. But that's not the sameWith all due respect how do i put a square slot in a center of a metal block.You can't possibly file it do you.

- Joined

- Feb 9, 2017

- Messages

- 5,250

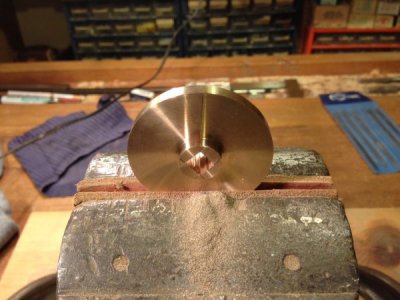

The problem for me with the die grinder was controlling it. I was doing a lot of precise work with it and after decades of using it freehand decided it was time to change it up. So I made a bench mount with the small table so I could control the work, not the die grinder. It works so much better I wish I'd done it years ago.This is a question I've been asking myself since the day I got a power tool .Is a power tool a good substitute of a machine tool like a die grinder with carbide burr can I use it to do free hand milling(sounds stupid tho)and how precise can I get assuming I have the best money can buy.I even tried it myself but found it to be a tough work.

Attachments

- Joined

- May 16, 2016

- Messages

- 1,698

When I stared as an apprentice Fitter/ turner/ toolmaker we were given a block of steel 1 1/8th " square, an engineers square, a 1" micrometer and a couple of files We had to make it 1.000" + - 0.002

' on all sides and square. most of us took about 3 shots at it and about two weeks. LAter on we learned how to operate lathes, mills, jig borers, surface grinders, pantographs, etc. we also learned how to use a die grinder, they became one of my favorite tools, I still use one today.

' on all sides and square. most of us took about 3 shots at it and about two weeks. LAter on we learned how to operate lathes, mills, jig borers, surface grinders, pantographs, etc. we also learned how to use a die grinder, they became one of my favorite tools, I still use one today.

- Joined

- Mar 16, 2016

- Messages

- 132

My old shop teacher was a terrible machinists. However he did teach me how to read a vernier scale, to understand the principles of cutting and tool shapes. Mostly he demonstrated that machines are only as accurate as the operators and to prove it he cut and filed a piece of 1/4" rod to a desired length to an accuracy of tenth of a thou. He did it in under 3 minutes all the while talking us through the process. Then challenged the class to repeat it in the remaining 15 minutes of class. None of us pulled it off. He did it with chop saw and a lapping stone.

- Joined

- Feb 1, 2015

- Messages

- 9,621

Whenever this discussion comes up, I think of Roy Underhill, the Woodwright's Shop, and Norm Abram, the New Yankee Workshop. Roy used tools that had been used in the 17th century and earlier while Norm always had the latest and greatest power tools. Both did great work in their own way.

The modern day machinists and engineers trace their origins to blacksmiths, the machinists/engineers of their time. There have been many intricate and exquisite mechanisms made without the benefit of modern machine tools da5ting as far back as the Middle Ages. In those days, to make a lock and key, a blacksmith would first make a key and then the lock to match the key. Essentially using one part as a gage for making a mating part. A useful technique, even now.

What machine tools have done for us is to allow us to efficiently make identical and interchangeable parts because the metrology is built into the machine itself. Hand working a part to match another part can be done but what would take minutes with a machine tool would take jours or days by hand. I recall cutting a keyway in an 1-1/2" shaft by hand, using a cold chisel, before I had a mill. The hand work took the better part of a day to accomplish and the results, although functional, were less than perfect. The mill would have completed the task in a matter of minutes.

I get satisfaction from hand work but the thought of making a complex part with all features matching the design to within a few thousandths by hand sends a cold shiver down my spine.

The modern day machinists and engineers trace their origins to blacksmiths, the machinists/engineers of their time. There have been many intricate and exquisite mechanisms made without the benefit of modern machine tools da5ting as far back as the Middle Ages. In those days, to make a lock and key, a blacksmith would first make a key and then the lock to match the key. Essentially using one part as a gage for making a mating part. A useful technique, even now.

What machine tools have done for us is to allow us to efficiently make identical and interchangeable parts because the metrology is built into the machine itself. Hand working a part to match another part can be done but what would take minutes with a machine tool would take jours or days by hand. I recall cutting a keyway in an 1-1/2" shaft by hand, using a cold chisel, before I had a mill. The hand work took the better part of a day to accomplish and the results, although functional, were less than perfect. The mill would have completed the task in a matter of minutes.

I get satisfaction from hand work but the thought of making a complex part with all features matching the design to within a few thousandths by hand sends a cold shiver down my spine.