- Joined

- Nov 10, 2013

- Messages

- 837

Sorry for the delay in getting the model numbers. One was in the shop and every time I was in there, something shiny caught my attention. One is a 192-613 and the other is a 192-601. Both are strictly metric and as others have pointed out, I can always sell them and buy what I need which I might do.

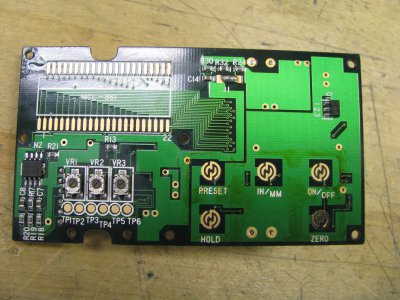

I'd still like to see a pic of the faces, one thing I've seen over many years of repairing gauges is that most companies don't design their electronic gauges to only do one thing, it's not cost effective. Often times there is a way to switch them even if internally. Other times a button sequence will do the trick.