-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Portable Boring Bar stand / table build

- Thread starter Gearhead88

- Start date

- Joined

- Dec 28, 2021

- Messages

- 17

- Joined

- Dec 28, 2021

- Messages

- 17

Lathe is still down , Parts are on order , I removed the entire electrical box so I could work on it on the bench.

Last edited:

- Joined

- Dec 28, 2021

- Messages

- 17

The lathe is still down , parts are on order . I have a couple of new contactors , they arrived the other day , I found those on ebay for cheap , I am waiting for a thermal overload relay to arrive from China.

I'm very disappointed at the lack of support / customer service from Busy Bee where this machine was purchased . It appears they are only interested in selling product , not after sales support . The manuals for these machines are poor , in the past some have included wiring diagrams , now , it appears that they leave that little detail out of the booklet. I tried to get some help from them , I would have bought the necessary parts there if they were interested in helping . They did get $360 out of me for a new electric motor .

In the mean time I've been busy doing other things.

I'm very disappointed at the lack of support / customer service from Busy Bee where this machine was purchased . It appears they are only interested in selling product , not after sales support . The manuals for these machines are poor , in the past some have included wiring diagrams , now , it appears that they leave that little detail out of the booklet. I tried to get some help from them , I would have bought the necessary parts there if they were interested in helping . They did get $360 out of me for a new electric motor .

In the mean time I've been busy doing other things.

- Joined

- Dec 28, 2021

- Messages

- 17

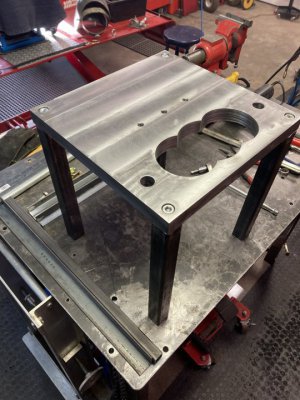

The work continues on my boring bar stand , the upper works is pretty much done . I still need to buy some more steel tubing to build the base.

I allowed room for the use of torque plates when they are needed .

The base , once built will put the top of the stand at 36" off the floor .

I'm going to use a cookie sheet as a chip tray.

I allowed room for the use of torque plates when they are needed .

The base , once built will put the top of the stand at 36" off the floor .

I'm going to use a cookie sheet as a chip tray.

- Joined

- Jan 2, 2014

- Messages

- 8,853

I'm very disappointed at the lack of support / customer service from Busy Bee where this machine was purchased . It appears they are only interested in selling product , not after sales support . The manuals for these machines are poor , in the past some have included wiring diagrams , now , it appears that they leave that little detail out of the booklet.

Often those machines are sold under different name and model other places (grizzly, jet, etc.) with better manuals.

It's worth a look for those manuals too .... if you can find the equivalent model.

Brian

- Joined

- Dec 28, 2021

- Messages

- 17

Yes , I found them a few weeks ago downloaded and saved a copy on my desktop and printed a few pages so I'd have a decent electrical schematic to work with . This machine is a variation on what is out there for chi-com 12 x 36 lathesOften those machines are sold under different name and model other places (grizzly, jet, etc.) with better manuals.

It's worth a look for those manuals too .... if you can find the equivalent model.

Brian

- Joined

- Oct 7, 2020

- Messages

- 2,116

Your boring bar stand is coming along nice!

Good luck with your lathe!

Good luck with your lathe!

- Joined

- Jan 2, 2019

- Messages

- 6,551

I have a 3 phase motor on my Taiwan 12x36, eliminated the control box entirely and have variable speed.

Love your boring setup in progress. I used to build racing kart motors and had to send out cylinders for boring. Would have been nice to do them in-house.

John

Love your boring setup in progress. I used to build racing kart motors and had to send out cylinders for boring. Would have been nice to do them in-house.

John

- Joined

- Dec 28, 2021

- Messages

- 17

I have a 3 phase motor on my Taiwan 12x36, eliminated the control box entirely and have variable speed.

Love your boring setup in progress. I used to build racing kart motors and had to send out cylinders for boring. Would have been nice to do them in-house.

John

I am not up to speed with what is required to do away with the electrical that is on it right now , that and I just bought a new motor at the begining of this episode so I`m probably gonna stay with the crap I have now.

I have a Sunnen machine to finish cylinders too .

It used to be lots of motorcycle shops did re-bores , valve jobs , rod bearing fitting , crankshaft rebuilding , engine building . That`s pretty much gone away in todays throw away society . Todays motorcycle dealerships are pretty much boutiques.

Last edited: