Hi Matt,

I am in that situation, purchased the PM-833TV with intentions to convert for CNC use. I ordered it in early January, and it is supposed to be delivered this Friday. I had several calls into Bruce's phone number, and didn't understand why I couldn't get a call back. I found out here about the bad news. I suppose they still have the kits in stock, and are hopefully re-grouping to keep going. But I also imagine the recovery will take time, nothing generates more grief and paperwork than an unexpected death...

I'm really hoping to salvage this project, do you have contact info for Jose, if it's ok to ask?

I have also contacted David at Arizona CNC Kits, asking if maybe one of his kits would crossover. He seems willing to work with me if I can get measurements to him for comparison. When it gets to my shop I'll see what I can find out. I don't have any experience with the other benchtop models so I don't have any clue what is the same or different between them. If anyone has the experience I'd welcome the help.

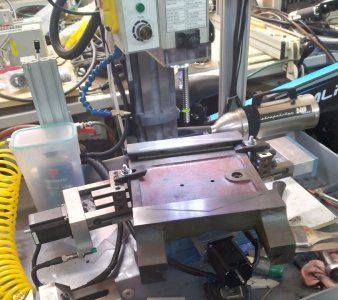

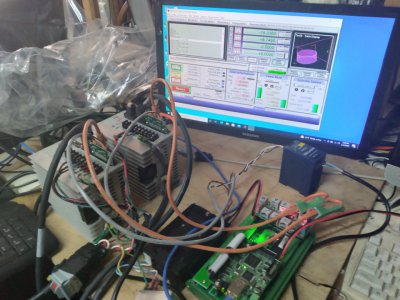

I got hooked on CNC when I worked for a shop that had a Tormach 1100 for production use. To train myself, I bought and converted one of the Sherline 5800 desktop units for CNC, using steppers, Gecko drivers, and Centroid Acorn. I learned Fusion 360 Design and Manufacturing modules and sucessfully made a lot of small parts. The PM-833TV really looked like a nice step-up option so I worked up a list of stuff to buy following the online example by Dr. D-Flo.