-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-833T Shop Made Base

- Thread starter ahazi

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,607

Great job, looks super solid, convenient tool storage right at the machine! You may consider expanding the chip pan to the LH/RH edges of your stand; the chips will fly. Or just a couple of pans on either side that are easy to dump and set back in place. Looking forward to seeing some of your projects.Here are few steps and the final result. Now I can move it to its permanent place and start playing...

View attachment 318258

View attachment 318259

View attachment 318260

View attachment 318261

View attachment 318262

Bruce

Thank you!Great job, looks super solid, convenient tool storage right at the machine! You may consider expanding the chip pan to the LH/RH edges of your stand; the chips will fly. Or just a couple of pans on either side that are easy to dump and set back in place. Looking forward to seeing some of your projects.

Bruce

This is the plan. I will add removable chip storage probably beyond the stand edges on the left and right so I can catch up as much as possible.

Ariel

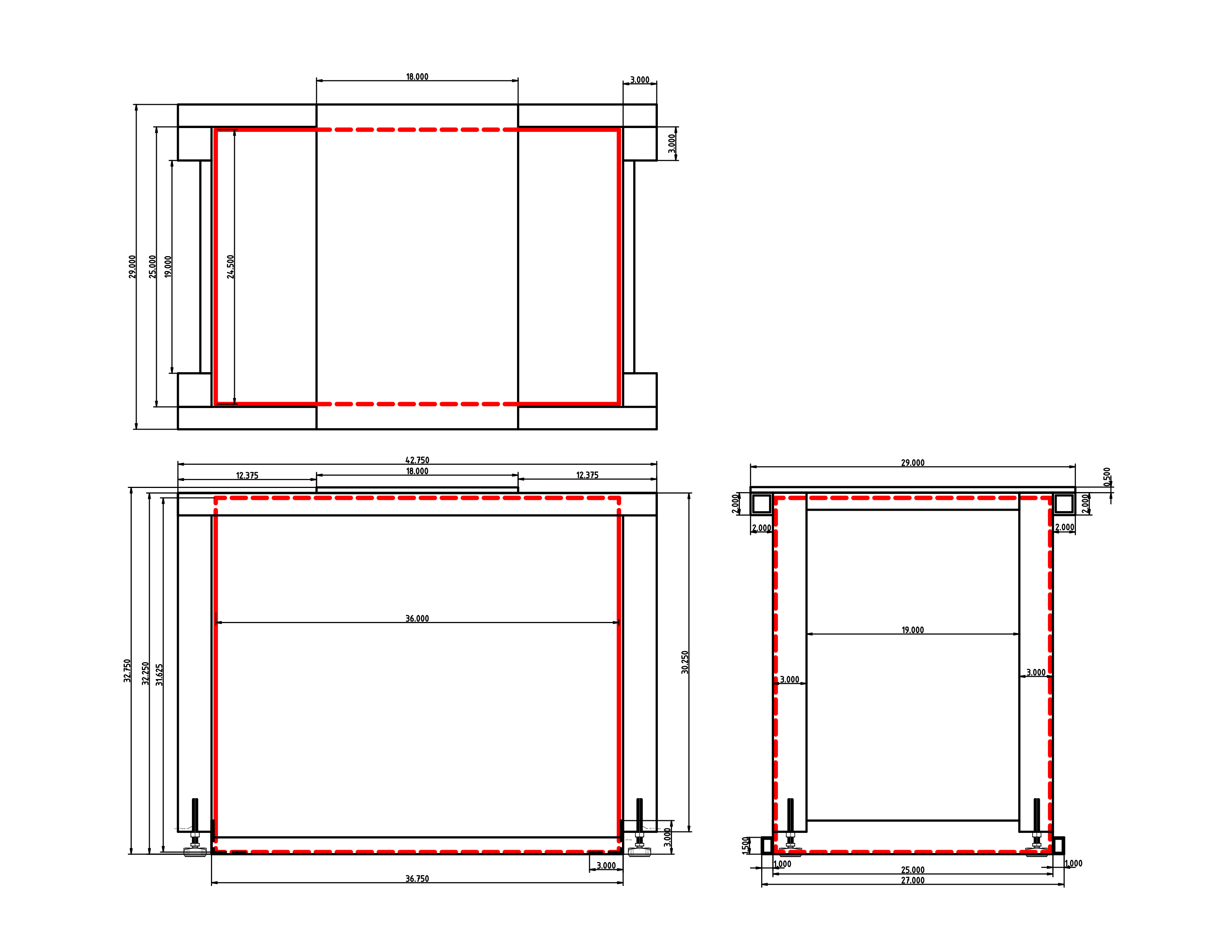

Here is the drawing (PDF and dxf in case you want to modify it) for the stand that I built. All the dimensions are for fitting the Home Depot toolbox. I am very happy from how it came out against my design goals.

This is the tool chest that I used:

https://www.homedepot.com/p/Husky-3...hest-Cabinet-in-Gloss-Red-H36TR6RXD/303643852

Please let me know if you have any questions.

Ariel

This is the tool chest that I used:

https://www.homedepot.com/p/Husky-3...hest-Cabinet-in-Gloss-Red-H36TR6RXD/303643852

Please let me know if you have any questions.

Ariel

Attachments

What size and thread are those bolts if you know? I bought an 833T but then had a medical issue that left it uninstalled for over a year. Recently got it up on the stand and the bolt I though went to it don't seem to want to thread. Before I screw something up I'd like to double check I'm using the right ones. ThanksQuestion: How to (properly) attach the PM-833T/TV to a shop made base?

I bought the chip tray from PM and I am building my own base with storage drawers. The tray has threaded (10mm) standoffs welded to the tray. Looks like the tray design was picked from the combined tray/base below (without coolant feed and drain.) It does not make sense to me to attach the mill only to the tray and attach the tray to my stand separately as it seems pretty flimsy. I am thinking of grinding out the standoffs and drill holes through the tray to allow 3/8" or 5/16" bolts for attaching to the 1/2" metal plate that is on top of my stand.

See below picture of the tray and the stand from PM. Looks like the standoffs have a rigid welded connection to the base.

View attachment 317758

- Is my theory correct?

- How did others solve the problem?

- Other ideas?

Ariel

The original standoffs threads are M10-1.5, the original bolts were about 4" long which is height of the base at the mounting holes.What size and thread are those bolts if you know? I bought an 833T but then had a medical issue that left it uninstalled for over a year. Recently got it up on the stand and the bolt I though went to it don't seem to want to thread. Before I screw something up I'd like to double check I'm using the right ones. Thanks

I hope this helps.

Ariel