In the long term, reading the motor issues with the stock single phase Chinese motor, a VFD conversion may ultimately be in the cards. That is excellent pricing for a WJ200 VFD and 2HP 3 phase Leeson motor.

I went over the top in my VFD conversion, mostly because I had a specific set of functions and interlocks I wanted to incorporate. I also had the time and background to do a more complicated set-up, and I would not recommend that level of complexity/build unless you are very familiar with doing so. It is always a learning exercise, at first I was quite intimidated by the whole process and the complexity of the command structure of these types of VFDs. That being said, it is a problem solving challenge, and you do it in a stepwise fashion.

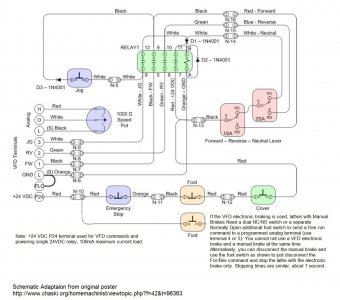

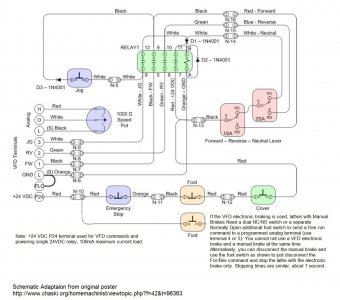

I would keep things simple for most VFD installs, the PDF description for the PM1236 is very straight forward and very cleverly done. I would get rid of the Jog direction switch and the green wire connection to the reverse terminal 10, see revised schematic adaptation. Also note that one should not use a manual lathe brake and the VFD brake at the same time. This is not addressed in the original schematic. I do not see this as a big issue, it may or may not be cause a problem, but the VFD brakes using a programmed algorithm you specify. If the manual brakes is faster than the VFD electronic brake, the VFD may add power to match the programmed braking curve. I use an electronic 1 second braking time so probably not a problem with this quick an interval, and may not require the additional foot switch/command.

It is possible to do the VFD conversion in a basic form with very little effort or changes to the system. If the most rudimentary conversion form, one could easily remove the 220V power to the forward/reverse contactors. Then connect P24 to one set of the contacts in the forward and reverse contactor to send commands to the VFD for the forward/Reverse commands. This retains all the safety and interlock features. The Jog function on the Hitachi requires two commands to be sent to the WJ200, Jog command and Forward or Reverse command at the same time. I see no reason to have a reverse Jog, so one just powers the existing jog switch from P24. When the jog button is engaged it connects P24 to the VFD terminal 3 JG and a diode (1N4001, 1N4004 or similar) wired to VFD terminal 1 (FW). The diode must be used, otherwise when the forward signal command is engaged it would backfeed the Jog command. Been there, done that.

The VFD is direct wired to the motor, 3 wires (should be shielded 14G). You need a breaker/on off switch to power up everything. Take it one step at a time. I will post the suggested programming variables when I get time.

Mark