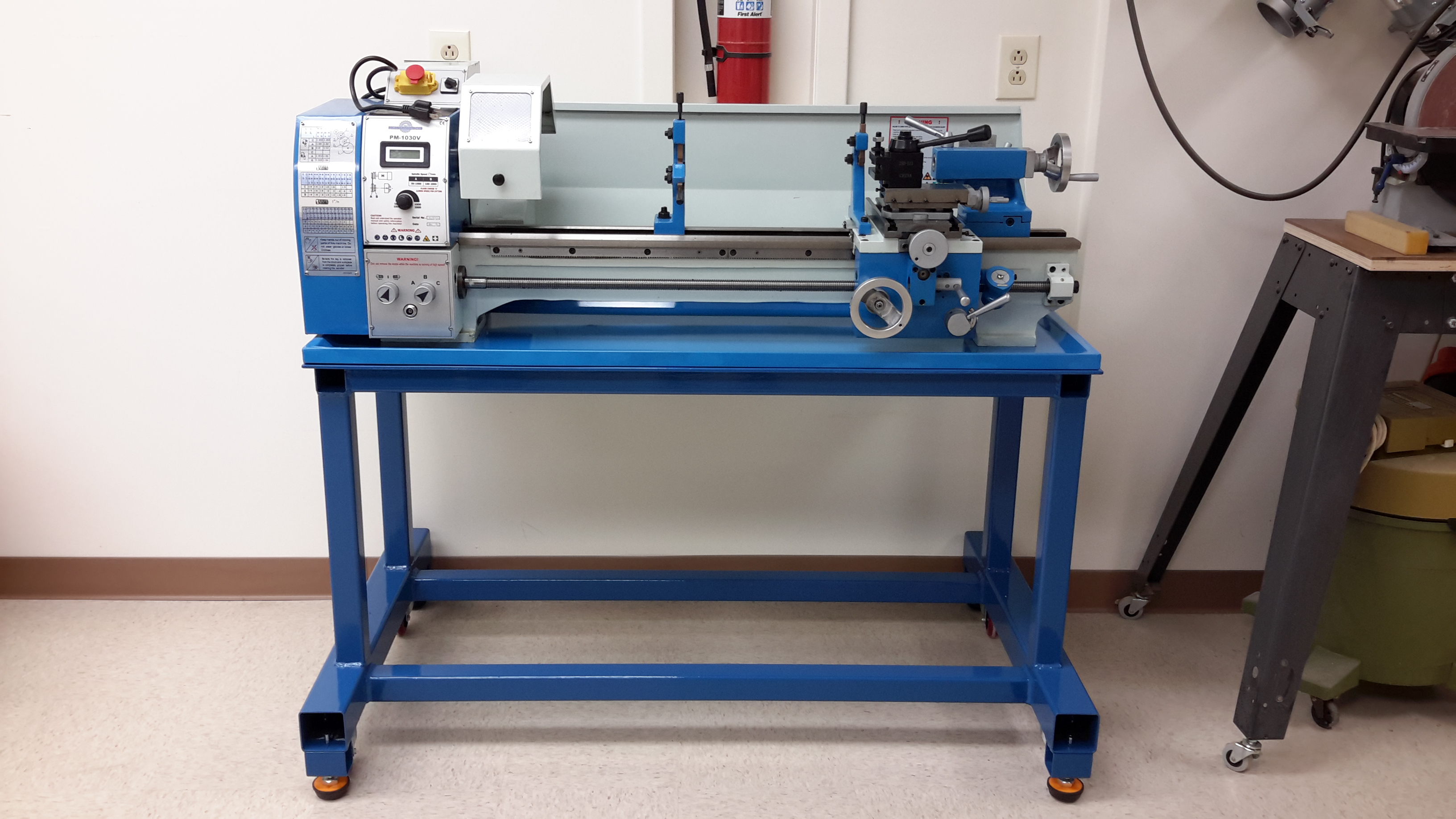

I got my 1030V mounted on the stand that I built for it today and started to get everything cleaned up. I am attaching a few pictures of the stand and lathe. The stand seems to work very well at this point and supports the lathe at a good height for me. The stand has a frame made of 2"x2"x1/8" tube, extended feet of 3"x3"x1/8" tube and a 1/4" plate steel top. I put 220 lb rated casters on it as well as 250 lb rated load levelers. When the assembly is in position, the load levelers will raise the casters off the floor. Hopefully tomorrow I can start playing around a little bit.

Jon

Sent from my SM-T700 using Tapatalk

Jon

Sent from my SM-T700 using Tapatalk