- Joined

- Feb 17, 2013

- Messages

- 314

Hi All,

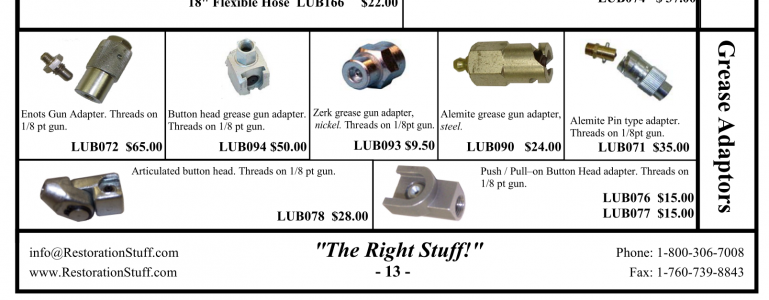

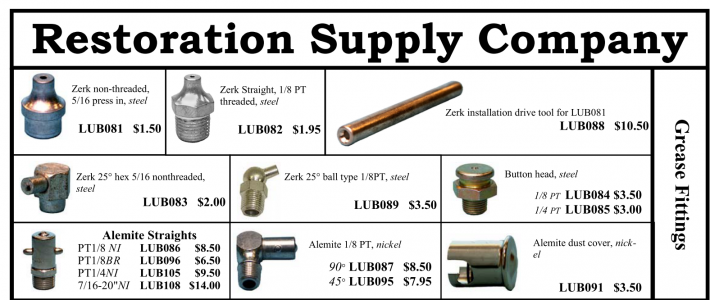

I have a new to me British made Cromwell lathe. It has some unusual oil fitting that I've never seen the likes of. Below is a picture of a couple of them - like a zerk fitting but with no provision to lock on. Some of them are on the underside of shaft supports, so the oil has to be under enough pressure to be pumped up to the bearing. Another member showed me an oil/grease gun in KBC, but I would still need a suitable female fitting to go on the nipple. Anyone have any ideas?

Thanks,

Michael

Sorry for the fuzziness of the pics but my phone has quit uploading photos, so I'm using an older digital camera.

I have a new to me British made Cromwell lathe. It has some unusual oil fitting that I've never seen the likes of. Below is a picture of a couple of them - like a zerk fitting but with no provision to lock on. Some of them are on the underside of shaft supports, so the oil has to be under enough pressure to be pumped up to the bearing. Another member showed me an oil/grease gun in KBC, but I would still need a suitable female fitting to go on the nipple. Anyone have any ideas?

Thanks,

Michael

Sorry for the fuzziness of the pics but my phone has quit uploading photos, so I'm using an older digital camera.

Last edited: