- Joined

- Feb 18, 2016

- Messages

- 451

Today I did a very simple project, but it took me several hours just the same. I'm building a robot base and I needed to make up some special axles. I also didn't want to spend any money on this project. Well, actually I already bought the wheels and tires, but I didn't want to put anymore money in it than I need to. So I went out in the field today and cut a couple pieces of steel rod off an old hay rake to make the axles from. The rods were bent so it took a while to try to get them straightened out as best as possible. I did that in a large vice with a hand-held sledge. Then I cut the axles to length, faced off the ends in the lathe and drilled center holes in the ends of them.

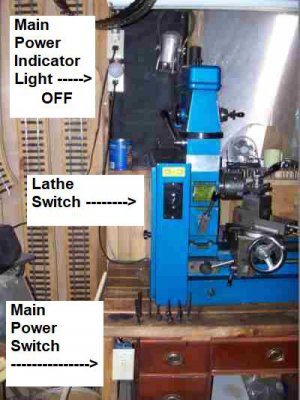

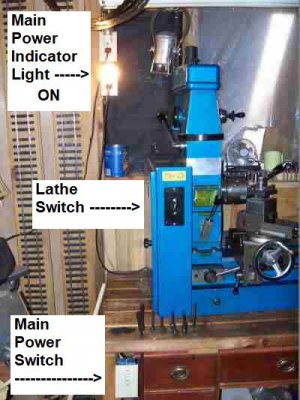

Then I had to turn down the ends ever so slightly to make them fit through the bearing races of my wheels. Finally I had to drill 8 cotter pin holes Two for each wheel so I could mount the wheels between the cotter pins with washer. This was the fun part. I needed to figure out a convenient way to drill these holes centered on the shaft. I came up with the following plan. I have a lathe/mill combo machine. So I figured that if I put the axles in the lathe chuck with the mill drill lined up on center this should do it. I could use the lathe chuck as the vice to hold the rods. So that's what I did. On the very first hole I also discovered that the chuck needs to be locked into place. There's no way to lock the lathe spindle so I had to hold the lathe chuck in the milling vice.

Notice in the following picture the mill vice is not holding the workpiece. It's just holding the lathe chuck.

I was then able to drill the axle with a center drill as shown above.

And finally with the cotter-pin drill shown below:

I had to drill two cotter pin holes for each wheel. One on either side of the wheel.

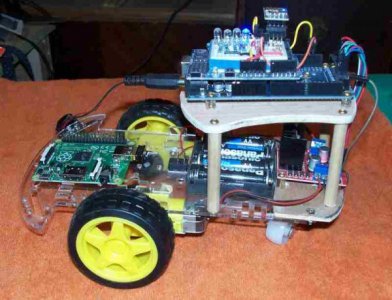

This is a photo of the finished axles with wheels attached.

This is going to be the base for a robot. And they are laid out here pretty much the way they are going to be on the robot.

Next I'll be making a wooden base as the main frame that will hold the batteries and motors. Once I get those mounted I'll need to make some bicycle chain sprockets. I've decided to use chain drive on all four wheels. One motor driving two wheels on each side of the chassis. There is no steering mechanism. Turning will be accomplished by running the right and left motors at different speeds. Or running one forward and one in reverse, which should allow this thing to turn around on a dime.

I'm excited about building this robot, but it's a project that can only be worked on during "free time". Which doesn't come up too often. Today I wasn't feeling very well so I decided not to do any "work". Then I said to myself, "Well go do something on the robot then". Who am I to argue with myself.

So I'm one tiny step further toward having a robot now.

But yeah, I really enjoyed doing the machine work on the lathe/mill. And yeah, I know I could have gotten by doing it on a drill press, but that wouldn't have been nearly as much fun.

Then I had to turn down the ends ever so slightly to make them fit through the bearing races of my wheels. Finally I had to drill 8 cotter pin holes Two for each wheel so I could mount the wheels between the cotter pins with washer. This was the fun part. I needed to figure out a convenient way to drill these holes centered on the shaft. I came up with the following plan. I have a lathe/mill combo machine. So I figured that if I put the axles in the lathe chuck with the mill drill lined up on center this should do it. I could use the lathe chuck as the vice to hold the rods. So that's what I did. On the very first hole I also discovered that the chuck needs to be locked into place. There's no way to lock the lathe spindle so I had to hold the lathe chuck in the milling vice.

Notice in the following picture the mill vice is not holding the workpiece. It's just holding the lathe chuck.

I was then able to drill the axle with a center drill as shown above.

And finally with the cotter-pin drill shown below:

I had to drill two cotter pin holes for each wheel. One on either side of the wheel.

This is a photo of the finished axles with wheels attached.

This is going to be the base for a robot. And they are laid out here pretty much the way they are going to be on the robot.

Next I'll be making a wooden base as the main frame that will hold the batteries and motors. Once I get those mounted I'll need to make some bicycle chain sprockets. I've decided to use chain drive on all four wheels. One motor driving two wheels on each side of the chassis. There is no steering mechanism. Turning will be accomplished by running the right and left motors at different speeds. Or running one forward and one in reverse, which should allow this thing to turn around on a dime.

I'm excited about building this robot, but it's a project that can only be worked on during "free time". Which doesn't come up too often. Today I wasn't feeling very well so I decided not to do any "work". Then I said to myself, "Well go do something on the robot then". Who am I to argue with myself.

So I'm one tiny step further toward having a robot now.

But yeah, I really enjoyed doing the machine work on the lathe/mill. And yeah, I know I could have gotten by doing it on a drill press, but that wouldn't have been nearly as much fun.