-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Parting Poll

- Thread starter BFHammer

- Start date

- Joined

- May 4, 2015

- Messages

- 3,583

Hi Wreck, I'm close to you. I used to work in Riverton . Everworth had a shop just off the highway . Way back in the 70 s. Herb North owned it . Did work for us pipe and the steel mill . I remember those 72 hour weeks. After a few months your a zombie yep I remember them well. Would those tools work on a planer ? If you think so I'd like one if you have enough.

- Joined

- Sep 29, 2014

- Messages

- 2,102

Doubtful, all turning tools with specialized uses, 2" round shanks as well. I have worked in machine shops for 30 years and have never seen a planer in use. I do on occasion use a Morrison key seater which is the same process yet only for internal keyseats.Hi Wreck, I'm close to you. I used to work in Riverton . Everworth had a shop just off the highway . Way back in the 70 s. Herb North owned it . Did work for us pipe and the steel mill . I remember those 72 hour weeks. After a few months your a zombie yep I remember them well. Would those tools work on a planer ? If you think so I'd like one if you have enough.

Crude but effective, Morrison does have an interesting method of advancing the DOC however.

- Joined

- Nov 23, 2014

- Messages

- 2,607

- Joined

- Apr 8, 2013

- Messages

- 1,982

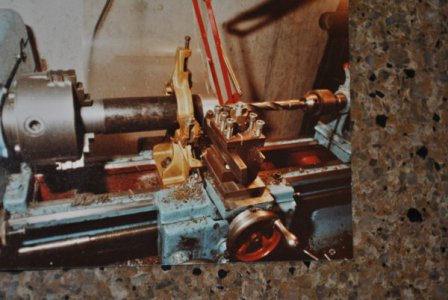

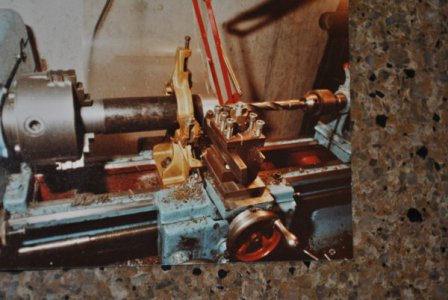

I use an aux holder so I can use a bigger blade. I found the biggest aid to parting is to eliminate the compound. I had an old 11 inch Logan that would part steel with at best 50/50 success rate. I eliminated the compound and it parted steel with no problems. I also eliminated the the compound on my G4003G Grizzly. That machine already parted well but without the compound it slices steel like butter at 200 rpm hand fed about as fast as I can go.

- Joined

- Sep 29, 2014

- Messages

- 2,102

She got the house, you got the old beater pickup (-:Parting is such sweet sorrow!