- Joined

- Oct 31, 2016

- Messages

- 2,645

I am not much of a welder. I have a small, light weight table that folds up when not in use. It lives outside 100% of the time. No cover of any kind. With the relatively low humidity in California especially in the summer months rust has not been a problem. If you want a cover I would make it out of Sumbrella (sp?) fabric like what is used on boats. It repels water and because it breaths moisture is not trapped under the cover. And it lasts forever. Not unusual for boat covers, dodgers, etc to last 15 to 20 years. The thread holding it together rots out way before the cover starts to deteriorate.

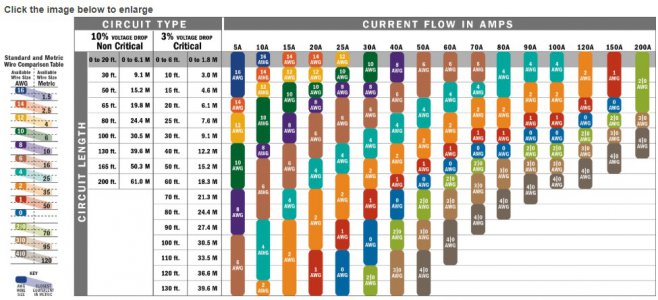

My welder is a HF flux core modified to be dcen and I power it with a 50' extension cord. I have not noticed any problems but then I probably don't know enough about welding to even know if I have a problem. My new place has a 240 volt 50 amp outlet in the garage. I am thinking about upgrading to a better welder. No idea what to get and probably couldn't afford it anyway. That welder would also run off of an extension cord. I'll ask a friend of mine about wire size. He worked for SCE and was responsible for the maintenance and repair of the transmission lines leaving the San Onofre Nuclear plant. He knows his stuff when it comes to sizing wire. He has been educating me about wire sizes. I'll report back on what he has to say.

My welder is a HF flux core modified to be dcen and I power it with a 50' extension cord. I have not noticed any problems but then I probably don't know enough about welding to even know if I have a problem. My new place has a 240 volt 50 amp outlet in the garage. I am thinking about upgrading to a better welder. No idea what to get and probably couldn't afford it anyway. That welder would also run off of an extension cord. I'll ask a friend of mine about wire size. He worked for SCE and was responsible for the maintenance and repair of the transmission lines leaving the San Onofre Nuclear plant. He knows his stuff when it comes to sizing wire. He has been educating me about wire sizes. I'll report back on what he has to say.