-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Options For High Speed Milling

- Thread starter TomS

- Start date

fwiw ive had success engraving alum with my 4200 rpm, running about 5-6ipm, WD40, I use a Micro 100 60* split point 1/8th shank, and .062 2fl ball from Harvey Tools

Once I get my auxiliary spindle up and running I'll give those cutters a try. With a spindle speed of 1970 I'd have to be at 2 IPM +/- to get the chip load where it needs to be. At that feed rate I'd have to shave twice before the program is done. LOL. The new spindle will go as low as 5000 rpm and as high as 30000 which gives me more options.

Tom S

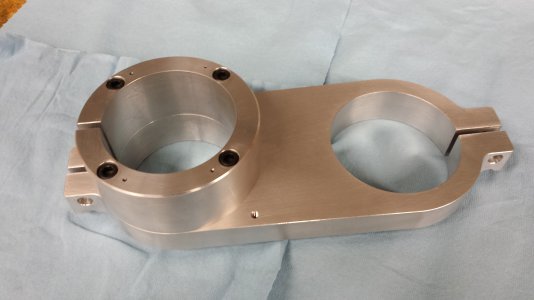

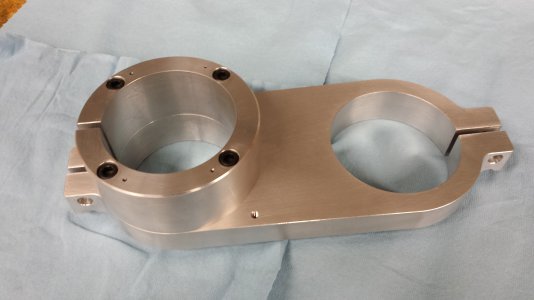

Today I finished up the router bracket and mounted the router on the mill. The bracket started out as a piece of 1-1/2" x 5" x 13" aluminum. I wittled it down to what you see in the pictures.

I ordered the Super-PID speed controller about a week ago. Hoping it gets here before Thanksgiving so I can wire up the electronics and start engraving. Here's a few pictures of the bracket and router on the mill.

Tom S

I ordered the Super-PID speed controller about a week ago. Hoping it gets here before Thanksgiving so I can wire up the electronics and start engraving. Here's a few pictures of the bracket and router on the mill.

Tom S

In between home projects and some traveling I finally got my high speed spindle up and running. I mounted a Porter Cable 1-3/4 HP router on a bracket that clamps to the quill. Spindle speed is controlled by a SuperPID speed controller. The SuperPID controls spindle RPM from 5000 to router max speed of 27500. It does everything as advertised. The only downside is their communication was not good.

Here's a shot of a 1/2" 2 flute carbide end mill taking a .050" wide x .050" deep cut in aluminum at 6135 RPM feeding at 30 IPM. It cut smooth as silk and this was reflected in the finish.

And a picture of the control panel. Pretty simple. I used a 8" x 8" x 4" plastic enclosure box. It houses the SuperPID circuit board, a 3" fan and a 5vdc and 12 vdc wall wart. I mounted an on/off switch so I don't have to reach into the mill enclosure to turn off the router. The router rpm didn't vary more than +/- 20 rpm while cutting. It's also got a heat sensor. It reads 8 deg C. A little cold in my shop today.

Here's a shot of a 1/2" 2 flute carbide end mill taking a .050" wide x .050" deep cut in aluminum at 6135 RPM feeding at 30 IPM. It cut smooth as silk and this was reflected in the finish.

And a picture of the control panel. Pretty simple. I used a 8" x 8" x 4" plastic enclosure box. It houses the SuperPID circuit board, a 3" fan and a 5vdc and 12 vdc wall wart. I mounted an on/off switch so I don't have to reach into the mill enclosure to turn off the router. The router rpm didn't vary more than +/- 20 rpm while cutting. It's also got a heat sensor. It reads 8 deg C. A little cold in my shop today.

Nice job, I'm jealous, I actually got my router sitting out so I can make a mount. I have a Bosch colt, but you can only get 1/4" collets for it so whatever

Thanks. Have you tried PreciseBits.com for collets?

Tom S