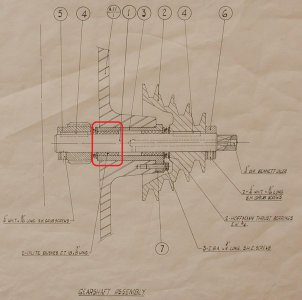

Working on my Boxford S200 I found some wear on the Oilite bronze bearing supporting the small spur gear side (the axle with the v-belt pulley).

Wear measured to ~0.1mm (~4thou). Now the questions I have:

- is this wear excessive? the axle is 19.05mm, so is 0.1mm relative to a 19mm bore

- what clearance would be adequate for such a bearing? I mean as new.

- I to not have "Oilite" sintered bronze available, I am thinking to plain bronze and a 0.02mm clearance, should it be ok?

Wear measured to ~0.1mm (~4thou). Now the questions I have:

- is this wear excessive? the axle is 19.05mm, so is 0.1mm relative to a 19mm bore

- what clearance would be adequate for such a bearing? I mean as new.

- I to not have "Oilite" sintered bronze available, I am thinking to plain bronze and a 0.02mm clearance, should it be ok?