-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New DRO for my PM-45... Help!!!

- Thread starter jgedde

- Start date

- Joined

- Jun 23, 2011

- Messages

- 786

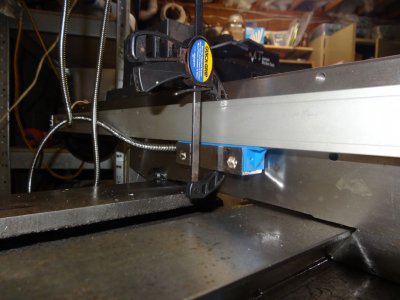

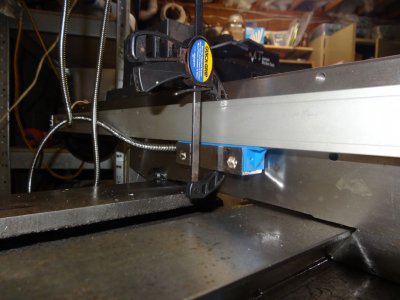

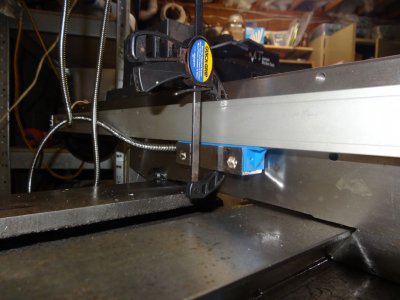

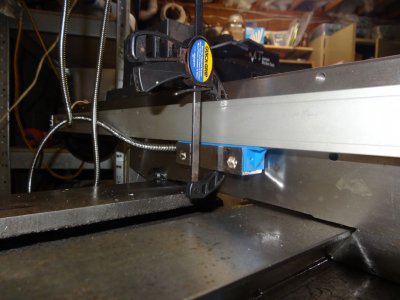

Thanks everybody! I think it's all falling into place. I've got the X scale mounted up except for having a way to drive the read head. Since the read head points down, and the screw holes come in from the back side of the head (facing the column), I think all I need to do is transfer punch the holes in the head to the bottom half of the table (i.e. fixed portion), then fabricate a shim to take up the space between the read head and the table. My only worry about this approach is having the head over constrained (the engineer in me is rearing his ugly head). If the scale isn't mounted EXACTLY right, or the bottom half of the table isn't ground exactly parallel to the top half (i.e. moveable section), then I'm wondering if I can damage the head or at the very least affect accuracy. Also, since the holes in the read head are tapped, I'd need to drill them out to make them clearance holes. I don't really relish the idea of drilling the read head.

I still haven't figured out how the DRO readout is supposed to be mounted. It looks like my setup is meant for a lathe... There is no included arm to mount the readout.

After that, I have one last detail... How to remount the way cover since the scale interferes with where it used to bolt up.

Ray, how is your X axis read head driven? I can't really tell from the photo.

Thanks again, fellas.

John

I still haven't figured out how the DRO readout is supposed to be mounted. It looks like my setup is meant for a lathe... There is no included arm to mount the readout.

After that, I have one last detail... How to remount the way cover since the scale interferes with where it used to bolt up.

Ray, how is your X axis read head driven? I can't really tell from the photo.

Thanks again, fellas.

John

- Joined

- Feb 22, 2012

- Messages

- 924

looking good, looks very similar to how I mounted mine:

https://sites.google.com/site/metworx/adventures-in-machining/sx3droinstall

https://sites.google.com/site/metworx/adventures-in-machining/sx3droinstall

- Joined

- Jun 23, 2011

- Messages

- 786

looking good, looks very similar to how I mounted mine:

https://sites.google.com/site/metworx/adventures-in-machining/sx3droinstall

Thanks Sharon! And your basement shop looks like mine too... Corner location for the mill, a pipe behind it, and a window above it!

The main difference is my walls are painted. I did that because I had a hairline crack in the foundation and water was seeping in. So, I tried that DRYLOK paint. It ultimately didn't work because the water just went behind the paint and came out at floor level. So, I had to repair the crack (chipped out the crack and filled it with hydraulic cement). But I noticed that where I painted the lighting was much better - so I painted the whole shop with leftover antique white latex. The shop just feels better (less like a dungeon) and the lighted is vastly improved.

Getting back to the DRO. It seems to work great. I ended up mounting the X scale head like I mentioned in post 12. Drilling out the tapped holes in the read head was a cinch. I made them very generous clearance holes to allow me to align the head.

The only thing I have left to do is make a way cover for the Y axis.

John

- Joined

- Feb 22, 2012

- Messages

- 924

sounds like this shop arrangement is a good one

water damage in basement is awful. in the previous place we lived we constantly had the basement flooded with every little drop of rain. had to raise everything on --2-- layers of shipping pallets and even that didn't always work.

I think painting also helps illuminate and spread out the lighting better as the light has better wall reflection to refract off of - when we own out place, I'll definitely have a fully finished work shop... until then once can only dream.

you'll love having that DRO feedback once finished, makes operations on the mill so much fluent when you can just turn those wheels and see the measurements as opposed to having to allow the LS to reegnage when changing direction and resetting the dials on each run.

water damage in basement is awful. in the previous place we lived we constantly had the basement flooded with every little drop of rain. had to raise everything on --2-- layers of shipping pallets and even that didn't always work.

I think painting also helps illuminate and spread out the lighting better as the light has better wall reflection to refract off of - when we own out place, I'll definitely have a fully finished work shop... until then once can only dream.

you'll love having that DRO feedback once finished, makes operations on the mill so much fluent when you can just turn those wheels and see the measurements as opposed to having to allow the LS to reegnage when changing direction and resetting the dials on each run.

Thanks Sharon! And your basement shop looks like mine too... Corner location for the mill, a pipe behind it, and a window above it!

The main difference is my walls are painted. I did that because I had a hairline crack in the foundation and water was seeping in. So, I tried that DRYLOK paint. It ultimately didn't work because the water just went behind the paint and came out at floor level. So, I had to repair the crack (chipped out the crack and filled it with hydraulic cement). But I noticed that where I painted the lighting was much better - so I painted the whole shop with leftover antique white latex. The shop just feels better (less like a dungeon) and the lighted is vastly improved.

Getting back to the DRO. It seems to work great. I ended up mounting the X scale head like I mentioned in post 12. Drilling out the tapped holes in the read head was a cinch. I made them very generous clearance holes to allow me to align the head.

The only thing I have left to do is make a way cover for the Y axis.

John